$2.25M Awarded to Develop Sustainable Energy Products from Waste Streams

A team of researchers in NC State’s College of Natural Resources and College of Agriculture and Life Sciences has been awarded a $2.25 million grant funded by the Department of Energy to develop sustainable biotechnologies sourced from solid waste streams. The project, titled Sargassum and Wood Waste for Aviation Fuel and Graphite (SWAG), will develop a technological process for the production of sustainable aviation fuel (SAF) and battery-grade graphite using sargassum and wood waste.

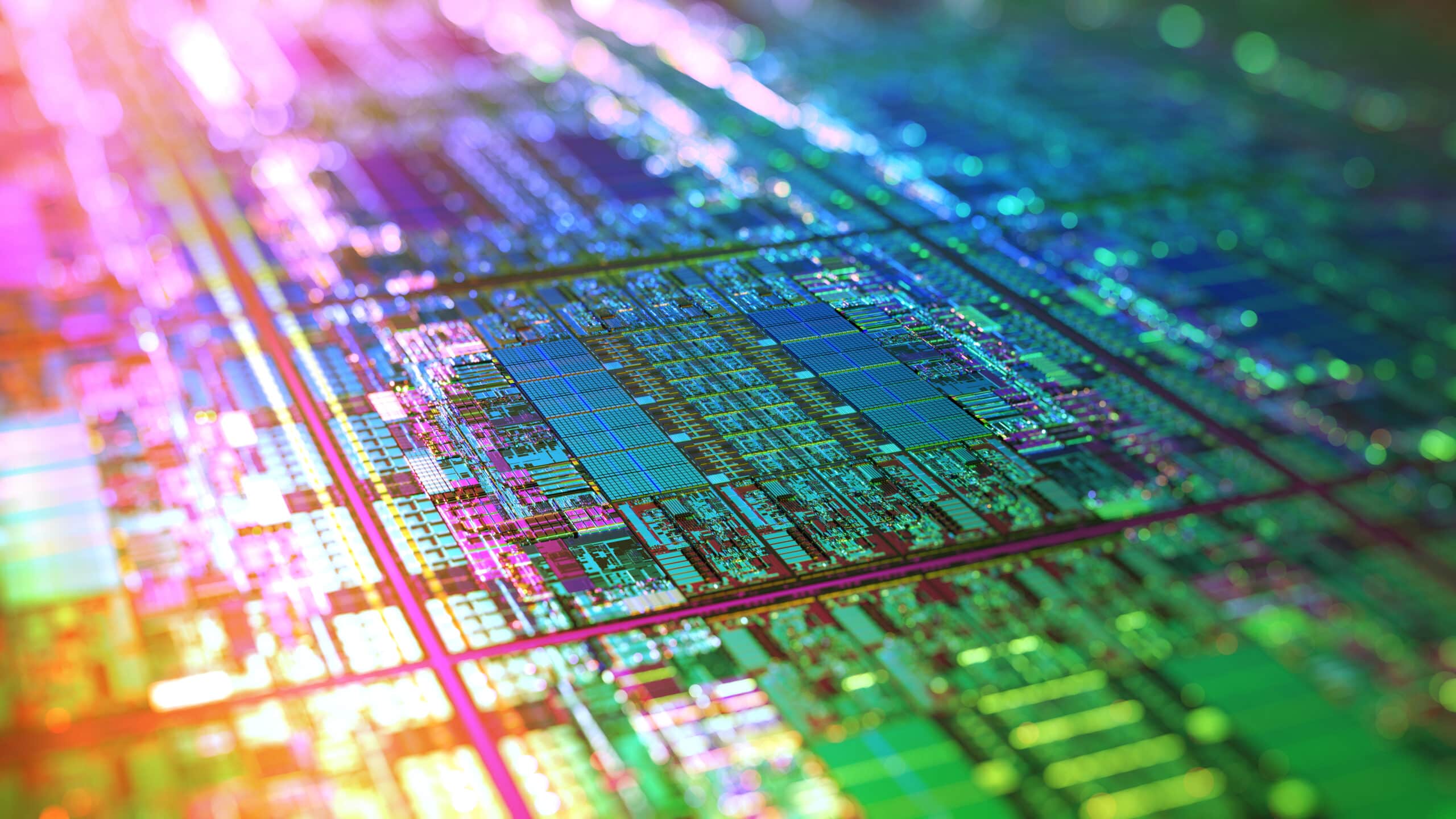

The current US administration’s ambitious climate goals will require the rapid proliferation of electric vehicles and renewable energy grid systems, with graphite making up roughly 30% of the mass of a lithium-ion battery. Battery-grade graphite is currently either mined or synthesized via heavily pollutive processes that threaten ecosystems and human health. With demand for these batteries expected to grow six-fold by 2032, according to Benchmark Mineral Intelligence, it’s estimated that nearly 100 new graphite mines and over 50 new synthetic graphite plants would need to be built to meet the projected demand. The SWAG project’s potential output technology could produce up to 61,000 tons of graphite per year, or roughly 3.4% of current synthetic graphite production worldwide from cheap, renewable resources.

Similarly, the project’s technology is capable of producing up to 78 million gallons of SAF, enough to meet 2.6% of the current administration’s goal of producing 3 billion gallons of SAF per year by 2030. Conventional aviation fuel is the dominant fuel source for air travel, contributing roughly 9 to 12% of all US transportation-related greenhouse gas emissions. The SWAG process estimates a reduction of SAF GHGs greater than 70%.

“Aviation fuel and synthetic battery-grade graphite are made with fossil petroleum feedstocks in rather unsustainable ways,” says Joe Sagues, assistant professor of Biological and Agricultural Engineering and a Co-PI on the project. “We believe that with the SWAG technology we can drastically reduce the greenhouse gas emissions associated with aviation fuel and battery grade graphite, while also increasing domestic jobs and creating other environmental and economic benefits.”

When sargassum washes up on beaches like in Puerto Rico, it rots, giving off a stench produced by hydrogen sulfide, which is a nuisance to nearby residents and tourists. While the marine macroalgae itself is harmless to human health, marine life living in the seaweed can become a skin irritant. “It’s one big biomass waste that there’s no real economical use for today,” says Sagues. With help from the University of Puerto Rico, researchers also plan to source wood waste from recent hurricane damage on the island, which will assist with relief efforts and infrastructural development projects. Wood waste from industrial forestry, pulp and paper, and lumber products are also viable feedstocks for the technology.

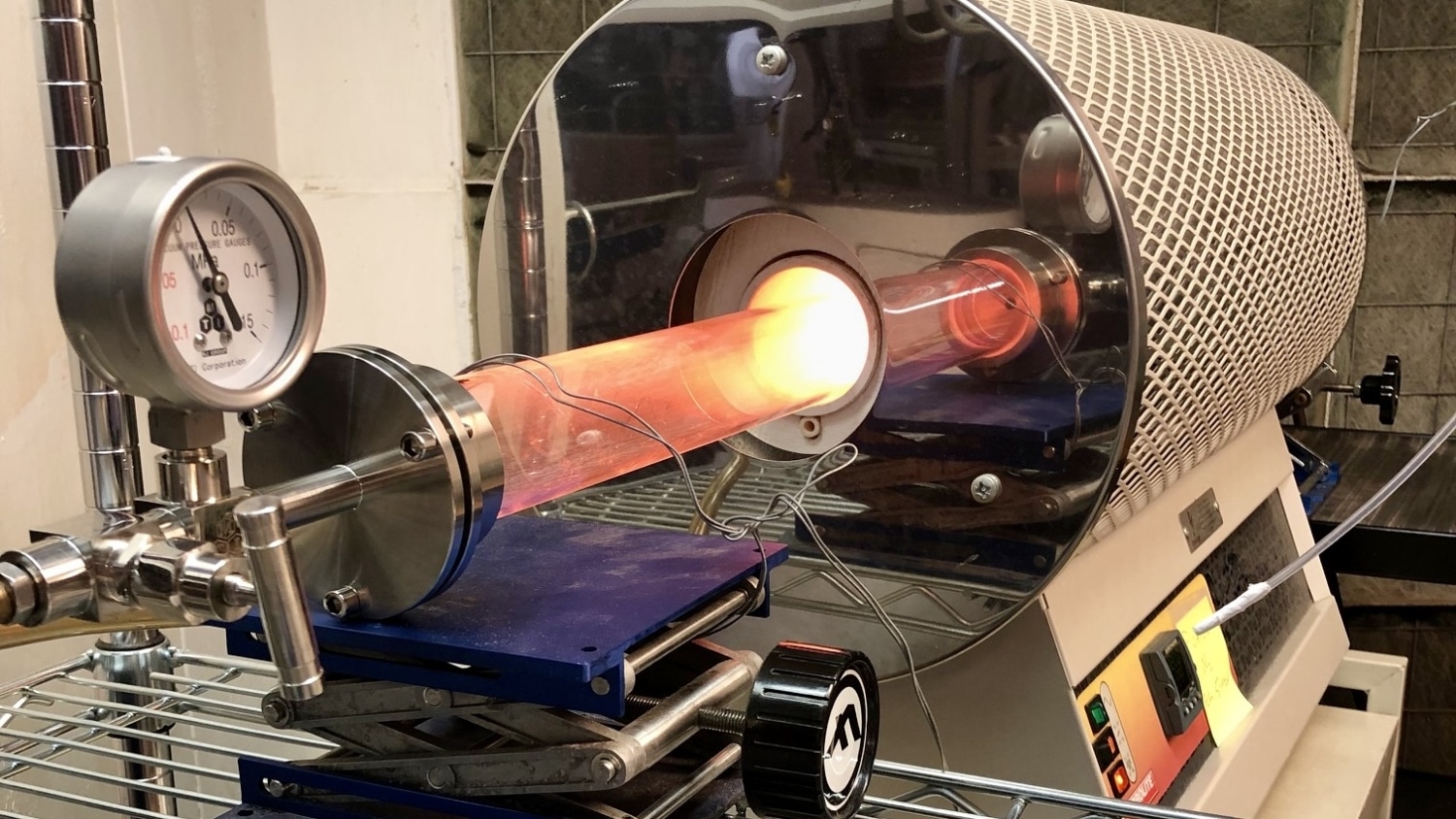

The team specifically identified wood waste and sargassum as interesting candidates because “you can do what’s called a pretreatment to separate two different components from the biomass. One of the components is rich in sugars, which can go on to fermentation for aviation fuel production. The other component is rich in lignin and other types of disordered carbon that can go onto graphite synthesis,” says Sagues.

Sagues and Sunkyu Park from the College of Natural Resources researched biofuels and bio-graphite for the past several years and successfully developed the baseline technology to be used in the SWAG project that works with a variety of biomass feedstocks. “The graphitization technology that we’ve developed is a catalytic process that requires an iron catalyst to work. For the SWAG project, we’re building on that by developing a recycling process for the first time whereby we’ll use a mixture of flotation, magnetic separation and auto-thermal catalyst regeneration,” Sagues explains.

While this project is primarily engaging with Puerto Rico, the technology being developed is compatible with a variety of feedstocks in different regions. “North Carolina stands to gain from this technology from the fact that we’re using wood waste as a major feedstock. There’s plenty of wood waste in North Carolina from the pulping and forestry industries.” To replace sargassum as the nitrogen-rich component of the biomass blend in North Carolina, adaptations of the technology could use different agricultural waste streams that are plentiful in the state, from crop residues to animal waste streams. “If it works well in Puerto Rico, it will work well in North Carolina and can be scaled up to bring domestic jobs and boost the state’s economy,” says Sagues.

NC State researchers will be collaborating on the project with the National Renewable Energy Lab (NREL), Birla Carbon, Fearless Fund and the University of Puerto Rico. Co-Principal Investigators on the project include Sunkyu Park from the College of Natural Resources, Joe Sagues, Department of Biological and Agricultural Engineering and Jacob Kruger from the NREL. Other key participants from NC State include Meg Blanchard from the College of Education, Richard Venditti, College of Natural Resources and Steve Kelley, College of Natural Resources.

This post was originally published in College of Agriculture and Life Sciences News.