Glues to Fuels: NC State, Partners Get Grant to Make Low-Cost Fuels from Forest Biomass

Create liquid fuels out of biomass products like wood waste and sawdust. Prove that this biofuels production technology can be performed on a larger scale than just the lab bench. And then show that the process is cheaper than coaxing ethanol from crops like corn.

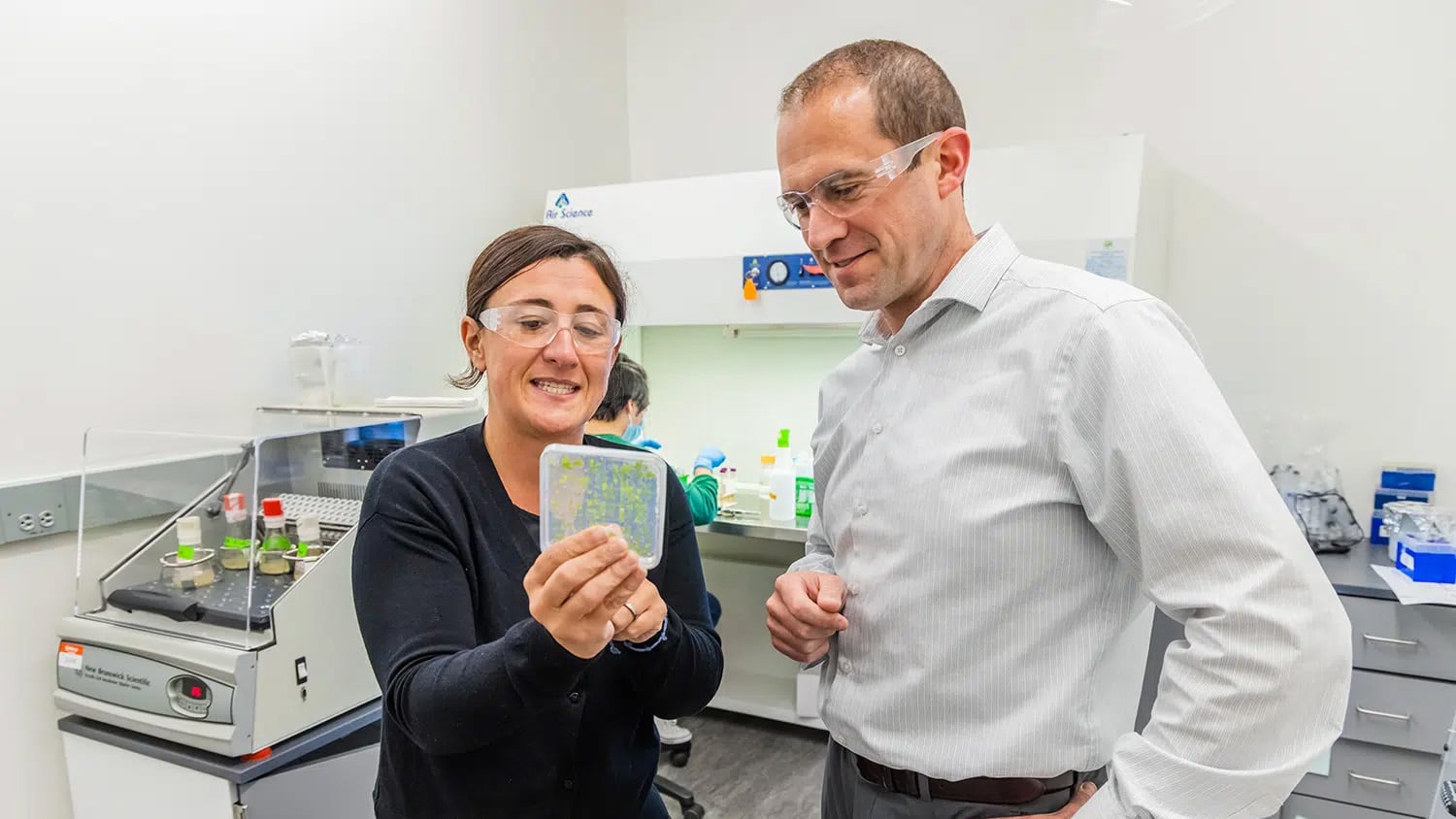

Those are the goals behind a three-year, $3.2 million research project funded by the U.S. Dept. of Energy that combines the efforts of North Carolina State University, RTI International and the University of Utah. The project – one of the first tangible outcomes of the newly formed Research Triangle Energy Consortium – combines the talents of Drs. Hasan Jameel and Steve Kelley from NC State’s Department of Wood and Paper Science and Drs. Henry Lamb and Steve Peretti from NC State’s Department of Chemical and Biomolecular Engineering.

One of the primary difficulties with creating biofuels from wood products is the glue-like substance called lignin found in wood. Peretti says that lignin is not a sugar, so fermentation methods – like those used in creating ethanol from corn, for example – don’t work.

Even though it’s harder to work with, Peretti likes lignin, calling it a “higher-energy feedstock almost like crude oil” that is lower in oxygen. Less oxygen, he says, translates to higher energy value per gallon.

“Demonstrating that a gasification process can be used to convert any biomass component – sugars, lignin, bark and different process residues – in any combination into liquid fuels” is a major goal of the project, Kelley says. Unlike the common methods used to ferment sugars into ethanol, gasification processes can use almost any biomass feedstock, circumventing the issues with decay of stored biomass.

Gasification processes can convert any biomass or hydrocarbon feedstock to a synthesis gas, or syngas, a reactive mixture of carbon monoxide and hydrogen. The process requires chemical catalysts to convert the syngas to the liquid fuels. The RTI team, lead by Dr. Dave Dayton, has unique experience in the development and evaluation of these syngas-to-liquid catalysts.

The process of making fuel out of wood waste starts in the woods with the collection of forest residues that are generated from timber harvesting or from thinnings used to prevent overcrowding and reduce fire hazards in the forest. This approach offers benefit to the forest landowners who can better manage their land, while minimizing the threat of fire or disease that comes from overcrowded stands, Kelley says.

A portion of these residues will be processed at the soon-to-be-operational Golden LEAF/NC State ethanol pilot plant, where engineers will produce large streams of lignin while also working to coax ethanol out of wood sugars. Various NC State researchers are working with industrial sweet potatoes, switchgrass, woody biomass and more in an effort to find reasonable alternatives to petroleum.

Lignin will be combined with the forest residues to serve as a lignin-rich feedstock for gasification and will be sent to the University of Utah, which has a pilot-scale gasifier. In the device, the material will be incinerated in little to no oxygen, producing the reactive syngas.

The syngas will then be cleansed of any remaining impurities – like soot – using technology developed by RTI. The cleansed material can then be converted at high pressure into ethanol or other fuels using the RTI catalysts.

“Anything that has organic molecules in it – clean wood, dirty wood, forest thinnings, bark, waste paper, solid waste, even plastics – can be used in this process,” Peretti says. “Diverting these materials from landfills to cranking out ethanol would help displace petroleum streams.”

- Categories: