Innovation to Save Lives: A Student’s Story, Part I

Editor’s Note: This is a guest post by NC State grad student Tate Rogers. Rogers came up with an idea to address the life-threatening challenge of human waste disposal in the developing world, and was part of a team that received funding from the Bill and Melinda Gates Foundation to pursue the idea further. Rogers will be presenting the project to the foundation this August in Seattle.

A lot changed for me in my final semester as an Environmental Engineering undergraduate at NC State. I found out I had been accepted into grad school, but more importantly I was able to be a part of Dr. Robert Borden’s Senior Design Course.

As the final project, he challenged the class with a request for proposals from the Bill and Melinda Gates Foundation, which was seeking ideas to improve the lives of the 2.6 billion people worldwide who live without proper sanitation. Some of the sanitation innovations they were searching for included improving or altering the current pit latrine design, re-use of the waste for agriculture and energy, and cheaper waste extraction methods from the pit latrines. I decided to focus on a new waste extraction method and after several days of toiling over possible fresh ideas, I came up with an answer.

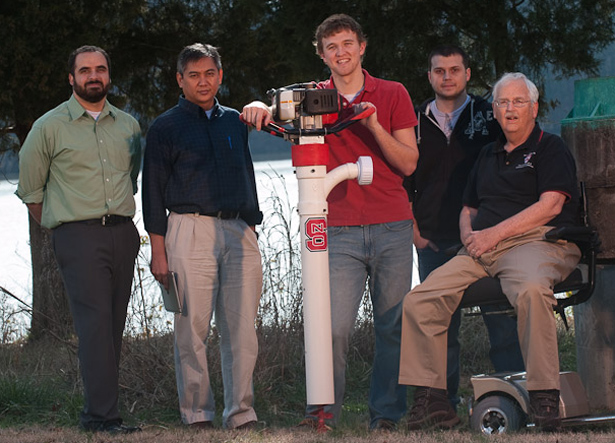

After making sure that this technology did not already exist, I ran the idea past Dr. Borden who immediately liked its simplicity and cost-effectiveness. We worked together through the summer and submitted the proposal in late May 2011 knowing it would be a long shot – since there were more than 2,000 submitted proposals. It wasn’t until a few days before I started grad school in that we were informed our project had been selected by the foundation and would be awarded the $100,000 Phase I grant to design, produce, and test the technology we had developed. This process would become the subject of my master’s thesis, which is ongoing.

So what was the technology we developed? Growing up on a small farm in North Carolina, I had helped dig my fair share of fence post holes with power augers. Power augers are a form of the ancient Archimedean Screw. They simply dig into the ground and lift the material to the surface. My idea was to insert a stationary pipe around the auger which would control the lifting of the waste up the flights of the auger and out through a tee fitting. The auger bit would be rotated by a gasoline motor that is easily operated by one user.

The design would make waste extraction affordable and feasible in any location, preventing the unsanitary emptying of the latrines by hand, and allowing pit latrines to perform their intended use. Sanitary waste removal will ultimately help prevent the spread of diseases that claim the lives of more than 4,000 children every day.

Since receiving the grant last fall, we have constructed, tested, and worked to perfect a prototype of the design. The prototype has produced flow rates up to 13 gallons per minute. It costs less than $750 to produce and we estimate the cost per pit latrine emptied to be less than $5 compared to $30-$80 for current technologies. We will begin field testing on the NC State dairy and hog farms this summer.

With the progress our project has shown through the first year, we have recently been invited to exhibit our prototype this August at the Reinvent the Toilet Fair on the Bill and Melinda Gates Foundation campus in Seattle. The fair is meant to bring together innovators, design experts, investors, advocates, and potential customers and showcase the progress in the reinvention of the toilet and other “toilet technologies” such as ours.

There will be 32 projects on exhibit from all over the world with hopes of furthering the advancement and implementation of their designs through collaboration with other experts in the field. For our exhibit, we will be running a five-foot version of our prototype that will lift a simulant waste from a 55-gallon drum and be powered by an electric motor for indoor display. We also hope to incorporate a video of the prototype being utilized on farms to show a true representation of its capabilities. The fair will be a great opportunity to introduce our project to possible investors, NGO presidents, future partners, and even Bill Gates himself.

We hope to find partners that will enable us to implement the technology in a suitable country for field testing in spring of 2013. Beyond that, if selected for the Phase II $1,000,000 grant, we hope to build several of our machines to be used in developing countries worldwide. This will require a great deal of collaboration. We hope to lay the groundwork for that collaboration at the Reinvent the Toilet Fair in August. I’ll write again after the event and let you know how it goes.

- Categories: