Lightweight Membrane Can Significantly Reduce In-Flight Aircraft Noise

For Immediate Release

Riding in a helicopter or airplane can be a noisy experience for passengers. But researchers from North Carolina State University and MIT have developed a membrane that can be incorporated into aircraft to drastically reduce the low-frequency noise that penetrates the cabin.

“This design is promising for making structures that are strong, lightweight, and sound-proof,” says Yun Jing, an assistant professor of mechanical and aerospace engineering at NC State and senior author of a paper describing the work.

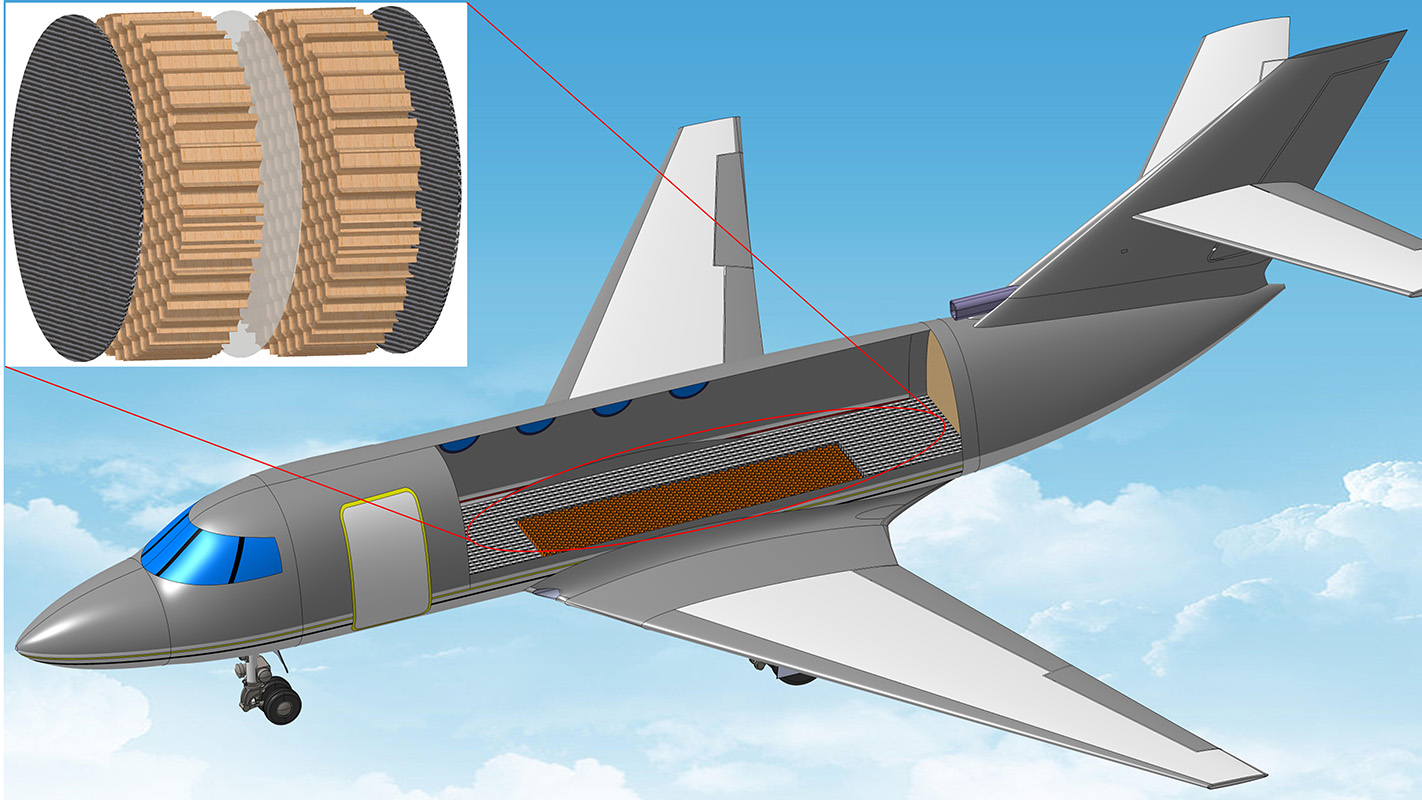

Aircraft designs incorporate light materials with a honeycomb-like structure into their wings and cabins. It’s the material that makes up the floor and ceiling of most airplane cabins. The sandwiched honeycomb structure makes it strong, and the light weight makes the aircraft more fuel efficient.

But these honeycomb structures are very bad at blocking low-frequency noise – like the noise of an aircraft engine. And adding insulation materials to limit the noise would add significant weight to the aircraft, making it much less fuel efficient.

NC State and MIT researchers have developed a possible solution.

They have created a thin, lightweight membrane that covers one side of the honeycomb structure, like the skin of a drum. When soundwaves hit the membrane, they bounce off rather than passing through.

“It’s particularly effective against low-frequency noise,” Jing says. “At low frequencies – sounds below 500 Hertz – the honeycomb panel with the membrane blocks 100 to 1,000 times more sound energy than the panel without a membrane.”

The membrane is made of rubber that is about 0.25 millimeters thick, and adds approximately 6 percent to the overall weight of the honeycomb panel.

“The membrane is relatively inexpensive to produce, and can be made of any material that does not impact the structural integrity of the honeycomb panel,” says Ni Sui, a Ph.D. student in Jing’s lab and lead author of the paper. “It could make flying much more pleasant for passengers –particularly in helicopters.”

The paper, “A Lightweight yet Sound-proof Honeycomb Acoustic Metamaterial,” is published online in Applied Physics Letters. Co-authors include Xiang Yan, Tai-Yun Huang, and Fuh-Gwo Yuan of NC State and Jun Xu of MIT. The work was supported in part by NC Space Grant.

-shipman-

Note to Editors: The study abstract follows.

“A Lightweight yet Sound-proof Honeycomb Acoustic Metamaterial”

Authors: Ni Sui, Xiang Yan, Tai-Yun Huang, Fuh-Gwo Yuan, and Yun Jing, North Carolina State University; Jun Xu, MIT

Published: online April 27, Applied Physics Letters

DOI: 10.1063/1.4919235

Abstract: In this letter, a class of honeycomb acoustic metamaterial possessing lightweight and yet sound-proof properties is designed, theoretically proven, and then experimentally verified. It is here reported that the proposed metamaterial having a remarkably small mass per unit area at 1.3 kg/m2 can achieve low frequency (< 500 Hz) sound transmission loss (STL) consistently greater than 45 dB. Furthermore, the sandwich panel which incorporates the honeycomb metamaterial as the core material yields a STL that is consistently greater than 50 dB at low frequencies. The proposed metamaterial is promising for constructing structures that are simultaneously strong, lightweight, and sound-proof.

- Categories: