Researchers Find Way to Make Metals Stronger Without Sacrificing Ductility

For Immediate Release

Researchers at North Carolina State University and the Chinese Academy of Sciences have developed a technique to make titanium stronger without sacrificing any of the metal’s ductility – a combination that no one has achieved before. The researchers believe the technique could also be used for other metals, and the advance has potential applications for creating more energy-efficient vehicles.

“Historically, a material is either strong or ductile, but almost never both at the same time,” says Yuntian Zhu, a professor of materials science and engineering at North Carolina State University and co-corresponding author of a paper describing the work. “We’ve managed to get the best of both worlds. This will allow us to create strong materials for use in making lighter vehicles, but that are sufficiently ductile to prevent the material from suffering catastrophic failure under strain.”

The key idea here is grain size, or the size of the crystals in the metal. Metals with a small grain size are stronger – meaning they can withstand more force before they start to deform. But metals with a small grain size are also less ductile, which means they can withstand less strain before breaking. Materials that aren’t ductile won’t bend or stretch much – they just snap. Conversely, metals with a large grain size are more ductile, but have lower strength.

The new technique manipulates the grain size to give the metal the strength of ultrafine-grained titanium but the ductility of coarse-grained titanium.

The researchers began by using asymmetric rolling to process a two-millimeter thick sheet of titanium. In asymmetric rolling, the sheet passes between two rollers that apply pressure to each side of the sheet, but one of the rollers rotates more quickly than the other. This not only presses the sheet thinner but, because of the different roller speeds, also creates a sheer strain in the metal.

In other words, the crystal structure within the titanium moves forward faster on the side of the fast roller than on the side of the slow roller. This effectively distorts and breaks down the crystalline structure, creating small grains in the material.

The researchers repeated the asymmetric rolling process until the metal was 0.3 millimeters thick, then exposed the sheet to 475 degrees Celsius for five minutes. This allowed some – but not all – of the small grains to consume each other and form large grains.

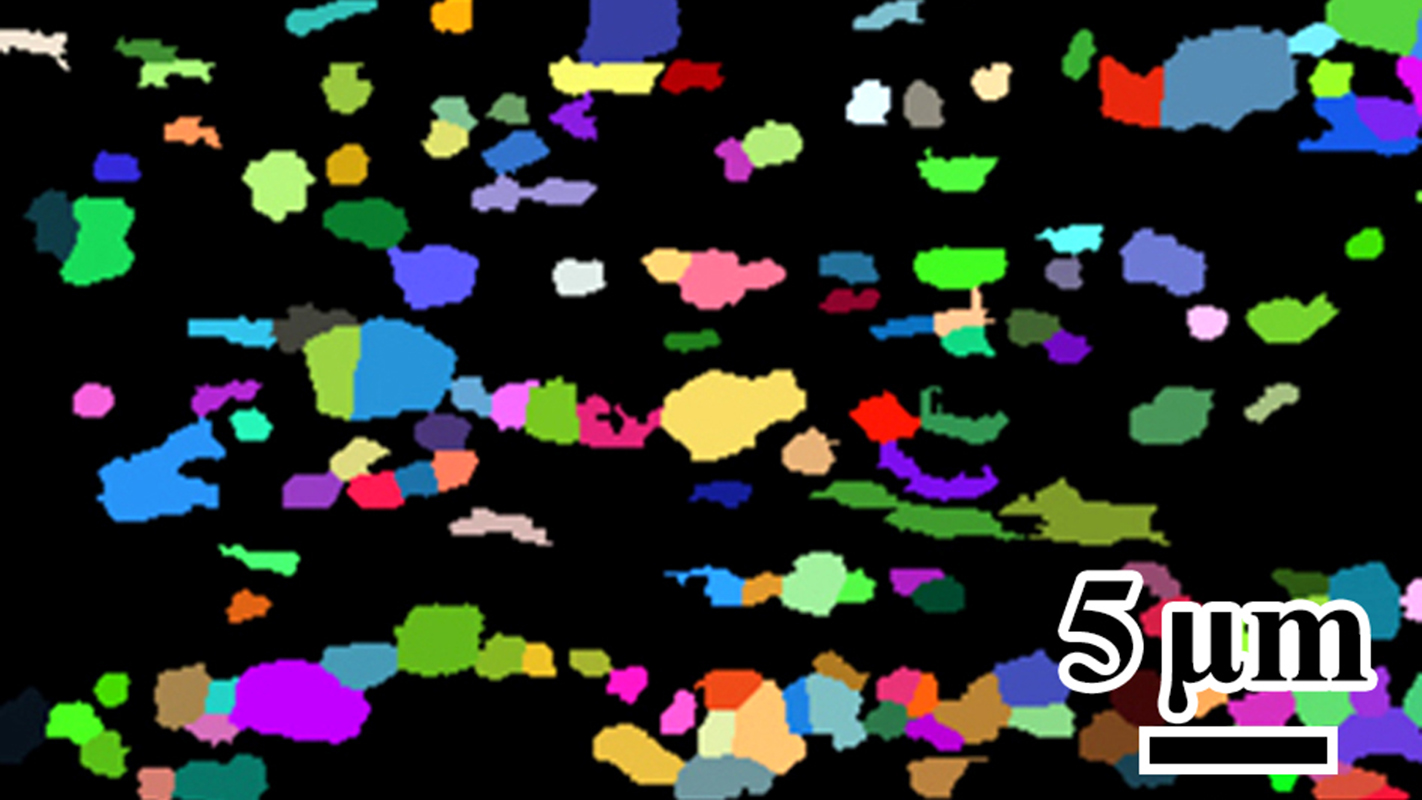

This second process creates a patchwork quilt of small and large grains. The large grains are laid out in long, narrow columns, with each column completely surrounded by a layer of small grains.

The resulting material is as strong as the small-grained titanium because the surrounding layer of small grains makes it difficult for the large grains to deform.

The material also retains the ductility of the large grains, because once enough strain is applied the small and large grains want to deform at different rates. But the different grain sizes have to coordinate with each other, much like traffic has to adjust to account for the slower cars on the road. The differential in grain sizes creates a phenomenon called strain hardening, in which the more the material is stretched, the harder it becomes.

“In addition to creating a metal with an unprecedented combination of strength and ductility, this material has higher strain hardening than coarse-grained titanium – which was thought impossible,” says X.L.Wu, co-corresponding and first author of the paper, who is based at the Chinese Academy of Sciences’ Institute of Mechanics.

The processes used in the new technique are already in widespread industrial use. “They just haven’t been used in this way,” Wu says. “So this should be fairly easy to scale up.”

Wu and Zhu are already working on projects to confirm that this technique would work for other metals and alloys.

The paper, “Heterogeneous Lamella Structure Unites Ultrafine-Grain Strength with Coarse-Grain Ductility,” will be published the week of Nov. 9 in the Proceedings of the National Academy of Sciences.

Zhu’s work was supported by the U.S. Army Research Office, under grant W911 NF-12-1-0009, and the National Science Foundation, under grant DMT-1104667. Wu’s work was supported by the National Natural Science Foundation of China and China’s Ministry of Science and Technology.

-shipman-

Note to Editors: The study abstract follows.

“Heterogeneous Lamella Structure Unites Ultrafine-Grain Strength with Coarse-Grain Ductility”

Authors: X.L. Wu, M.X. Yang, F.P. Yuan, and Y.J. Wei, Chinese Academy of Sciences; G.L. Wu and X.X. Huang, Chongqing University; Y.T. Zhu, North Carolina State University and Nanjing University of Science and Technology.

Published: Nov. 9, Proceedings of the National Academy of Sciences

Abstract: Grain refinement can make conventional metals several times stronger, but this comes at dramatic loss of ductility. Here we report a heterogeneous lamella structure in Ti produced by asymmetric rolling and partial recrystallization that can produce an unprecedented property combination: as strong as ultrafine-grained metal and at the same time as ductile as conventional coarse-grained metal. It also has higher strain hardening than coarse-grained Ti, which is hitherto believed impossible. The heterogeneous lamella structure is characterized with soft micro-grained lamellae embedded in hard ultrafine-grained lamella matrix. The unusual high strength is obtained with the assistance of high back stress developed from heterogeneous yielding, while the high ductility is attributed to back-stress hardening and dislocation hardening. The process discovered here is amenable to large-scale industrial production at low cost, and might be applicable to other metal systems.

- Categories: