Chancellor’s Innovation Fund Helps Turn NC State Research Into Real-World Solutions

At NC State, we know discoveries made here can change the world. And this year, six promising projects will receive support from the Chancellor’s Innovation Fund (CIF), helping researchers turn their discoveries into market-ready solutions.

“NC State continues to show why we are considered among the country’s top universities for commercializing research,” says Wade Fulghum, interim executive director of NC State’s Office of Research Commercialization. “The CIF is just one of a number of ways we help our innovative faculty commercialize their research for world-changing impacts.”

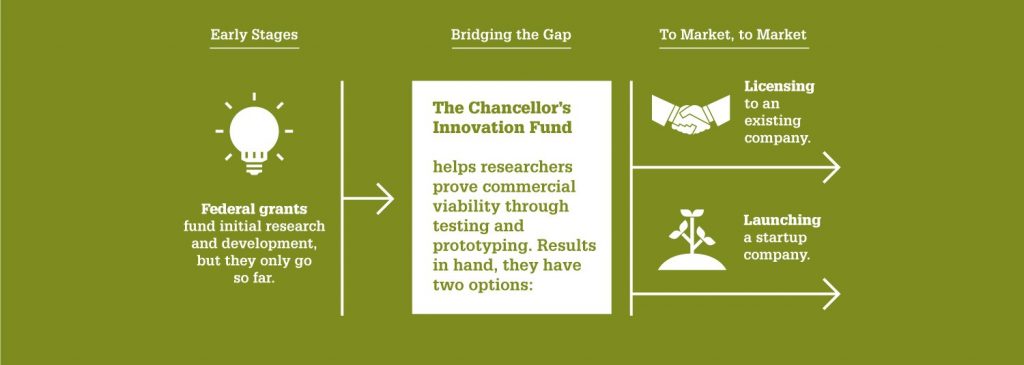

NC State established the CIF in 2010 to help researchers bridge the gap between publicly funded research and the point at which discoveries are developed enough to secure private funding.

To date, the CIF has granted nearly $3 million to 45 projects — which have attracted over $53 million in follow-on funding. These projects have generated 24 startup companies, 45 license agreements and more than $1.1 million in licensing revenue.

The work of this year’s CIF awardees ranges from a novel technique for infusing coffee into foods to groundbreaking developments in disease treatment — including a potential alternative to chemotherapy.

Purifying Therapeutic Antibodies Faster and More Efficiently

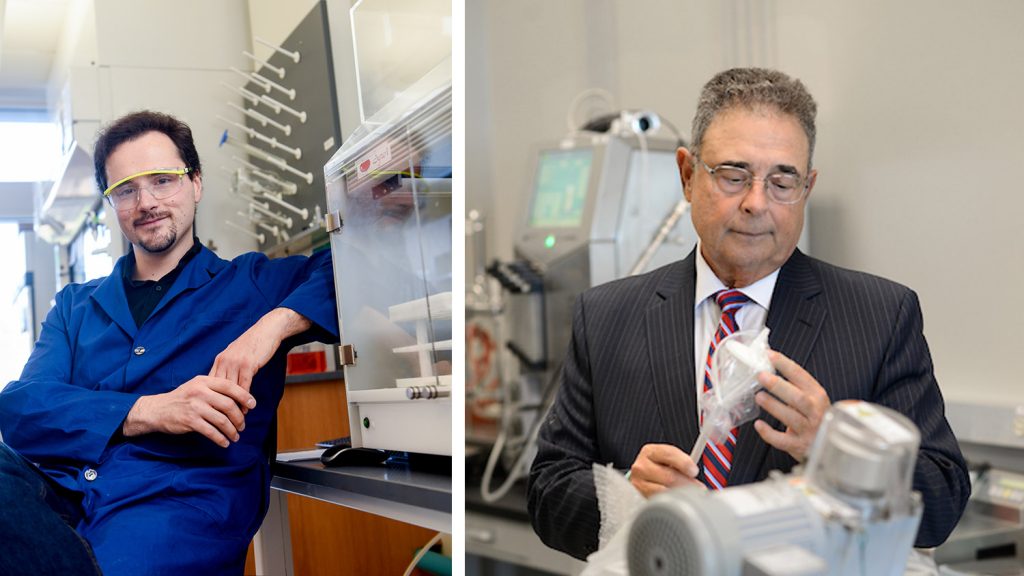

Chemical engineers Stefano Menegatti and Ruben Carbonell, director of the Biomanufacturing Training and Education Center (BTEC), have developed novel adsorbents — called “PepMix” — that transform the purification of anticancer and autoimmune therapies. Current purification methods are burdened by high costs and long processing times, causing roadblocks for patients in need of lifesaving drugs at affordable costs.

PepMix fundamentally changes the industrial purification of biotherapeutics — morphing it from a multistep process to a continuous one-step process, while also filtering out dangerous impurities more effectively. Together, these attributes are poised to have a game-changing effect on productivity. CIF support will be used to scale-up the operation at BTEC, demonstrating compatibility with industrial equipment and compliance with FDA-mandated purity and potency standards.

Making Coffee a Direct Ingredient in Foods

Dairy processing experts Gary Cartwright and Carl Hollifield have discovered a way to convert coffee beans into a direct food additive, allowing for unprecedented flavor and caffeine potency in coffee-infused products. In today’s fast-paced world, coffee-infused products are everywhere — from ice cream and beer to lotions and cosmetics. Not surprising, given that nearly 80% of Americans are coffee drinkers.

Making coffee-infused products currently requires brewing coffee, then removing the water to create a concentrate that can be added to the products. But with the ability to convert coffee beans into a direct additive, the brewing step — which wastes coffee grounds, water and energy — is bypassed altogether. CIF support will be used to make flavored product samples that will go to potential commercial partners for evaluation.

Creating Better Electronic Displays

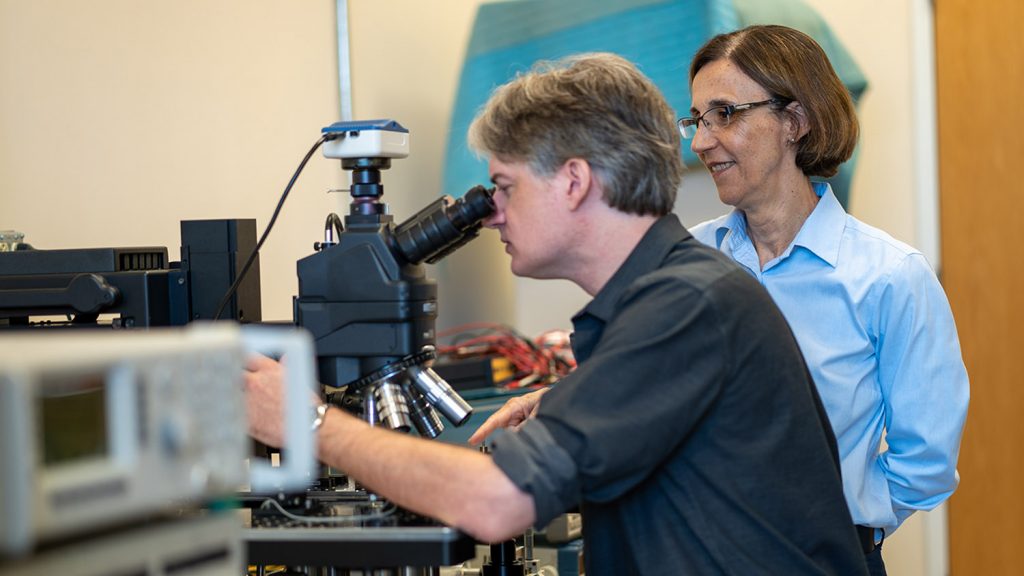

Ph.D. student Pedro Vergara and professor Leda Lunardi, of the Electrical and Computer Engineering Department, have developed technology that creates sharper, more vibrant screen displays that also use less power. To do this, they’ve combined the best qualities of the two main display types on the market — emissive and reflective — while eliminating the drawbacks of each.

Emissive displays, used in most smartphones, make indoor reading easy and produce high-quality images, but they eat up considerable power and can’t reflect sunlight. They can also cause eye strain with prolonged use. Meanwhile, reflective displays — used in reading tablets like Amazon’s Kindle — consume much less battery and practically eliminate glare. But they lack the image quality and touch-response time of emissive displays.

Vergara and Lunardi’s technology reduces glare more effectively than displays like the Kindle while providing video capability, faster response time and longer battery life. CIF support will be used to build a small-scale, fully functional prototype.

A Promising New Tool in the Fight Against Cancer

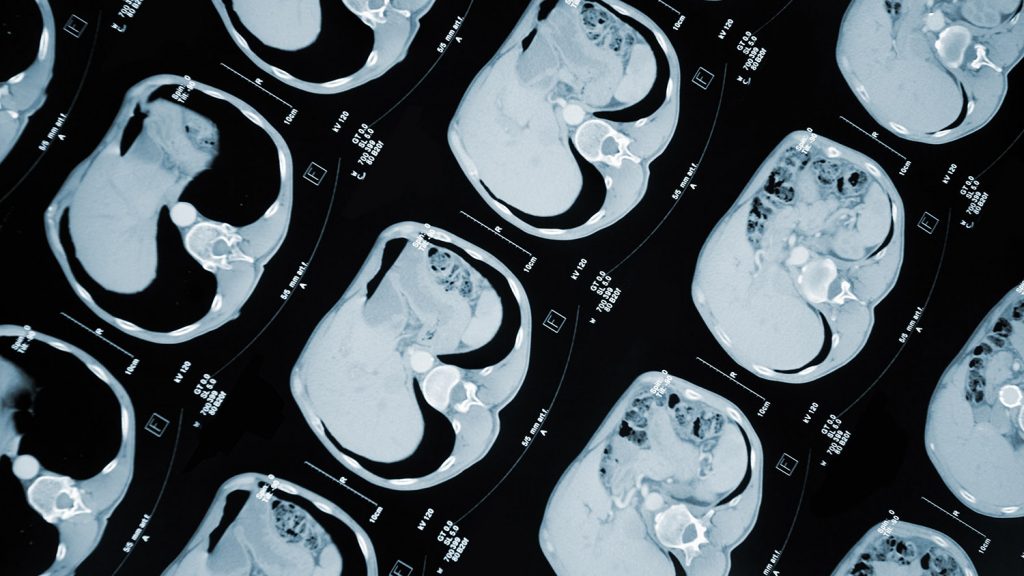

Michael Sano, of UNC-Chapel Hill and NC State’s Joint Department of Biomedical Engineering, has developed a treatment that could become an alternative to chemotherapy and radiation treatment for inoperable tumors.

According to the American Cancer Society, one in three people will have cancer at some point in their lifetime. Surgical removal of tumors can be curative, but many tumors form so close to major blood vessels that surgery becomes challenging or impossible. That means the vast majority of cancer patients have to endure chemotherapy. Because chemotherapy can’t distinguish cancerous cells from healthy ones, it can cause a range of adverse side effects.

Sano’s therapy uses electrical pulses and mild heating to selectively target and kill cancer cells — leaving underlying blood vessels and nerves undamaged. The therapy is also fast, with the potential to treat most tumors in under seven minutes. And because it spares critical structures, it may also shorten the healing process.

CIF support will be used to conduct a large-animal preclinical safety and reproducibility study needed for FDA approval.

Accelerating the Path to Clinical Trials for In Vivo Gene Editing

Jorge Piedrahita, Randall B. Terry Jr. Distinguished Professor of Translational Medicine and director of the Comparative Medicine Institute, and his Ph.D. student Kathryn Polkoff are developing a pig model that promises a path to safer, more cost-effective clinical trials and eventual FDA approval for gene-editing therapies.

Gene editing is widely regarded as the future of treating and correcting genetic disorders in humans. NC State food science professor Rodolphe Barrangou’s 2007 discovery of CRISPR-Cas presented a new world of gene editing possibilities. But to become a reality for human healthcare, the delivery methods must be proven to be precise, safe and effective.

Piedrahita and Polkoff’s model, using fluorescent proteins found in jellyfish, identifies whether a gene-editing therapy reached the right place in an organism — and whether the intended result occurred — at a single-cell level. The precision of this data will make clinical trials considerably safer and more effective, increasing the likelihood of the model becoming the industry standard and helping gene editing reach its potential.

CIF support will be used to create the model using methods that increase the commercialization potential of the model.

Using CRISPR to Unlock the Capabilities of Gene Editing for the Forestry Industry

Leveraging the combined expertise of the College of Natural Resources’ Forest Biotech Group (FBG) and the College of Agriculture and Life Sciences’ CRISPR lab, FBG Director Jack Wang and CRISPR pioneer Rodolphe Barrangou have discovered how to edit tree stem cells without using added DNA. Forests and forest products are a $700 billion global industry and a critical part of North Carolina’s economy — contributing $32 billion a year and representing the state’s largest employer among manufacturing sectors.

Thanks to research done by groups like FBG, we’ve known for years which genes could be edited to save the forestry industry potentially hundreds of millions of dollars. But until now, it wasn’t possible to edit genes without creating trees that are classified as genetically modified organisms, which aren’t viable due to serious environmental concerns.

The new delivery system uses CRISPR technology to alter the DNA, creating trees that are genetically indistinguishable from those found in nature (and therefore not considered GMOs). However, these trees could be produced in as little as 12 months, as opposed to the 15 years it can take with traditional breeding methods.

CIF support will be used to further test the CRISPR-based delivery system and prove the feasibility of whole-tree generation from the edited stem cells.