A Refrigeration Revolution — Advanced on Centennial Campus

Phononic found its first home at NC State. Now, the startup’s innovative solid-state cooling technology is heating up the refrigeration industry.

Inside your household refrigerator, old-school cooling technology is likely running the show. In fact, bulky compressor systems have dominated the refrigeration industry for over a century.

But a 21st-century challenger is gaining momentum. Startup Phononic’s leading-edge semiconductor cooling technology offers an alternative that’s more compact and more sustainable.

The company found its launchpad on NC State’s Centennial Campus in 2011. Now valued around $280 million, they say access to the university’s top-tier technology and talent helped them to scale up and succeed.

A Thermoelectric Solution

The first working vapor-compression refrigeration system — which gave way to today’s standard fridges — was built in 1834. Around the same time, French physicist Jean Peltier discovered the basis for thermoelectric refrigeration.

More than 180 years later, new technological breakthroughs have empowered Phononic’s semiconductor cooling solution to compete.

“We’re entering and disrupting markets where many believed a thermoelectric solution couldn’t exist,” said Phononic’s CEO, Tony Atti.

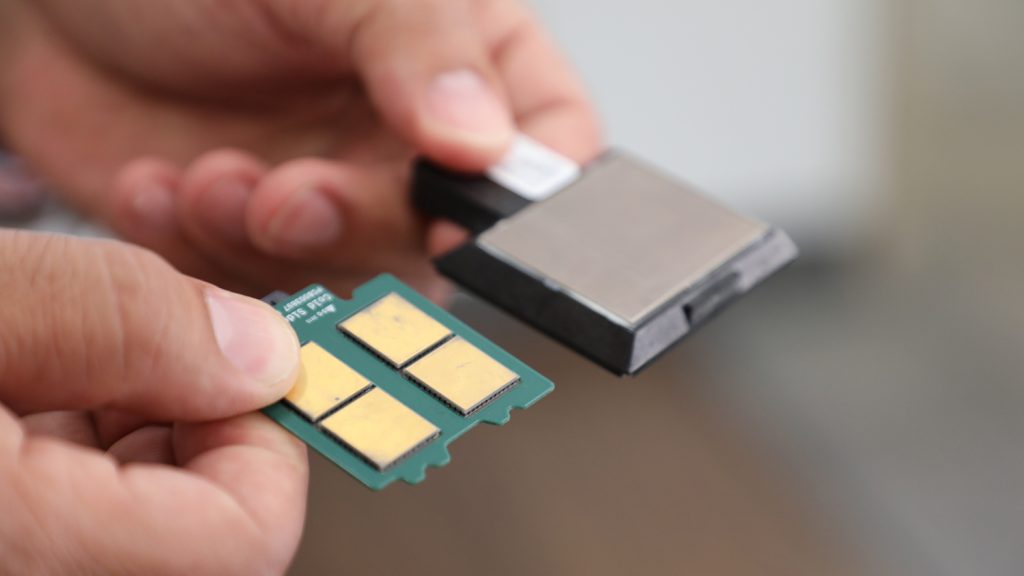

Inside the company’s thermoelectric chips, an electric current pushes heat from one side to the other to create a cooling effect.

This new approach offers improved temperature control and energy efficiency — while also eliminating chemical refrigerants found in your average refrigerator.

Today, Phononic’s technology is used to cool sophisticated lasers in fiber optic and 5G data communication. And hospitals like UNC Rex Healthcare now rely on thermoelectric refrigerators and freezers to safeguard thousands of dollars’ worth of lifesaving drugs and vaccines.

The company has also drawn the attention of food and beverage companies such as Pepsi Bottling. Phononic’s slim fridges can store more products in a single unit. What’s more, they allow retailers to keep tempting treats that require refrigeration (like ice cream) right at the checkout counter.

The Search for Centennial Campus

During its first year and a half, Phononic operated virtually. But the startup’s team quickly realized they’d need a physical space to start building semiconductor chips. And finding the right spot proved to be a nontrivial task.

Atti kicked off a nationwide search to find the company’s first home. He investigated opportunities across the country, including Silicon Valley, Phoenix, Austin, Boston and ultimately, Raleigh.

“I was looking for clean room manufacturing space and semiconductor manufacturing equipment. But I was also looking for scientists with a deep background in material science and process engineering,” he said. “That math brought us to Centennial Campus.”

According to Atti, several factors made NC State stand out:

Speed

Phononic was able to get up and running on Centennial Campus at an unprecedented rate.

“There’s not a lot of locations like that in North America, let alone the world, that would allow you to bring a team on board, on campus and hired into a fabrication facility in a matter of days and weeks — rather than months, or in many cases, years,” Atti said.

Infrastructure

When it was time to turn their product into a reality, Phononic’s team had needs well beyond standard office space and a solid internet connection.

On Centennial Campus, employees could get their hands dirty in the clean room, working with NC State’s best-in-class semiconductor equipment and developing the processes that ultimately gave rise to their products today.

NC State’s infrastructure served as inspiration when it came time to build Phononic’s own 35,000-square-foot semiconductor fabrication facility in Research Triangle Park.

The space also helped land investments. Potential partners could visit Phononic’s offices and see their scientific concepts — and their business model — come to life in real time.

“They knew that the data that I was presenting to them wasn’t just manufactured in an office,” Atti said. “They could see where that data was being generated, where the chips were being manufactured, where the chips were being tested. And they could see that it was done quickly, with professional best standards in place.”

People

NC State’s pipeline of talent was another draw. Over the past decades, the university has been a hotbed for compound semiconductor materials research — used in lasers and LEDs, but also crucial for Phononic’s thermoelectric devices.

When Atti’s team needed expertise in materials science and process engineering, they found it right on campus. Today, one-third of the company’s employees are NC State graduates.

“That unique skill set is hard to find around the country and it’s right in our back door,” said Atti.

“Phononic’s collaboration with NC State is an example of the mutual benefits that can be gained from a university-industry partnership,” said Leah Burton, director of NC State’s industry alliances and Centennial Campus partnerships. “Since joining campus in 2011, they have been a strategic partner, collaborating with our faculty and students to solve new challenges.”

Getting an ASSIST

In addition to bringing NC State talent on board as employees, Phononic also benefited from faculty expertise.

Once on campus, Atti was connected with the Larry K. Monteith Engineering Research Center (MRC), led by Mehmet Ozturk. His research and development and process engineering teams had access to the MRC’s semiconductor manufacturing equipment, and they worked closely with faculty from the center to tackle day-to-day challenges.

A partnership with the Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST) Center was another game-changer.

The National Science Foundation-funded research center focuses on developing disruptive technologies (such as wearable devices) to provide people with personalized, long-term monitoring of their health.

Joining forces in 2011, Phononic was one of ASSIST’s earliest industry partners.

Both groups saw thermoelectric’s potential. Beyond cooling applications, the technology also holds promise in ASSIST’s areas of interest, such as the internet of things and healthcare.

Aiming to translate innovative research into commercial products, the center relies heavily on collaborations with industry. ASSIST’s partners have access to their intellectual property, trained students and cutting-edge facilities and equipment across campus.

Phononic was able to work side by side with NC State researchers to conduct materials investigations. They used ASSIST’s testing laboratories and got critical feedback from faculty to improve their materials.

“We’re really thrilled to see all of Phononic’s successes,” said Veena Misra, the center’s director and a professor in electrical and computer engineering.

NC State worked with us to develop the underpinning of our technology.

“They’ve worked with our students and our researchers, and they’ve used our facilities for understanding their materials,” she said. “We’ve also worked with them in writing some joint proposals for furthering the maturation of thermoelectric technologies.”

Phononic and ASSIST’s initial partnership has seeded new opportunities, and the benefits continue to compound over time.

“NC State worked with us to develop the underpinning of our technology. But as that relationship blossomed, we were able to help the university land National Science Foundation grants,” Atti said.

Today, ASSIST is pursuing research in market areas that Phononic hopes to incorporate into their product roadmap in the future.

“Companies like Phononic are critical here because, with their involvement, we can get new resources and new funding streams to explore new directions,” Misra added.

A Cooler Future Ahead

Eight years later, Phononic is on strong footing. And Atti credits NC State’s role early on as helping the startup get there.

“We have real products, real technology, real revenue, and we’re manufacturing and selling chips all over the world,” he said.

Phononic still maintains strategic ties with NC State. Atti works closely with the university’s faculty, collaborating on research and development and advising on grants. And with a staff of 150 and counting, Phononic turns to the Wolfpack as a pipeline for interns and full-time employees.

Now that the startup has shown thermoelectric technology can thrive in the refrigeration industry, it’s embarking into new arenas. In the next few months, Phononic will be incorporating their chips into air conditioners and climate control solutions for the first time.

It ultimately allowed us to scale and move to the present state that we’re in today.

As the company grows and continues to disrupt new industries with solid-state cooling, Atti credits Centennial Campus as more than a first home.

“Centennial wasn’t just a proving ground for the science and the technologies. It was where Phononic became a company and a family. It ultimately allowed us to scale and move to the present state that we’re in today,” said Atti.