3D Images of Fabric ‘Sandwich’ Can Help Measure Textile Friction

To quantify exactly how itchy a wool sweater might be when worn directly against the skin, or how soft a blanket spread on your bed can be, North Carolina State University researchers developed a method of measuring fabric’s roughness using 3D imaging.

In the journal ACS Applied Materials & Interfaces, researchers reported on a series of experiments in which they used an imaging tool – X-ray micro-computed tomography – to take 3D images of the surface of fabric in order to calculate the surface geometry, and measure the impact on friction. Their method can quantify skin-textile interface at a microscale without destroying the fabric.

“We need ways to definitively measure friction to help the textile industry tune fabrics to be suitable for specific applications,” said the study’s corresponding author Kavita Mathur, associate professor of textile and apparel, technology and management at NC State. “We have textiles for apparel, for athletes, that are worn by patients, and that go into furnishings. Friction can be anywhere – not just against the skin. Ultimately, we envision using this method to ensure fabrics are not too abrasive for their end-uses, whether they are destined to end up on a hospital bed where irritation can lead to bed sores, or on an athlete or into furnishings.”

The Abstract sat down with Mathur to understand how 3D images can be used to measure friction:

The Abstract: Why do you need to develop a new way to measure fabric friction?

Mathur: The textile industry currently uses tests that require an instrument, specifically a metal probe, that rubs back and forth against a small piece of fabric to give an indication of how rough or smooth the fabric is at the micron level. The metal probe represents neither our skin properties nor the actual interaction.

My graduate student, Ruksana Baby, is working on a friction test method capable of mimicking the human skin response to fabric at varying conditions. This will allow us to investigate skin-textile interactions for diverse applications like sports apparel, health care and medical textiles, military apparel, firefighter’s protective clothing and more.

TA: How did you take the images of fabric?

Mathur: We used a computing device – a new instrument at our labs in the Analytical Instrumentation Facility – to take an image of a cross-section of the length and depth of the fabric. So we know exactly, layer by layer, how the fabric was composed. It’s non-destructive in terms of getting inside the fabric. This tells us the geometry of the fabric from the fiber level to the fabric level.

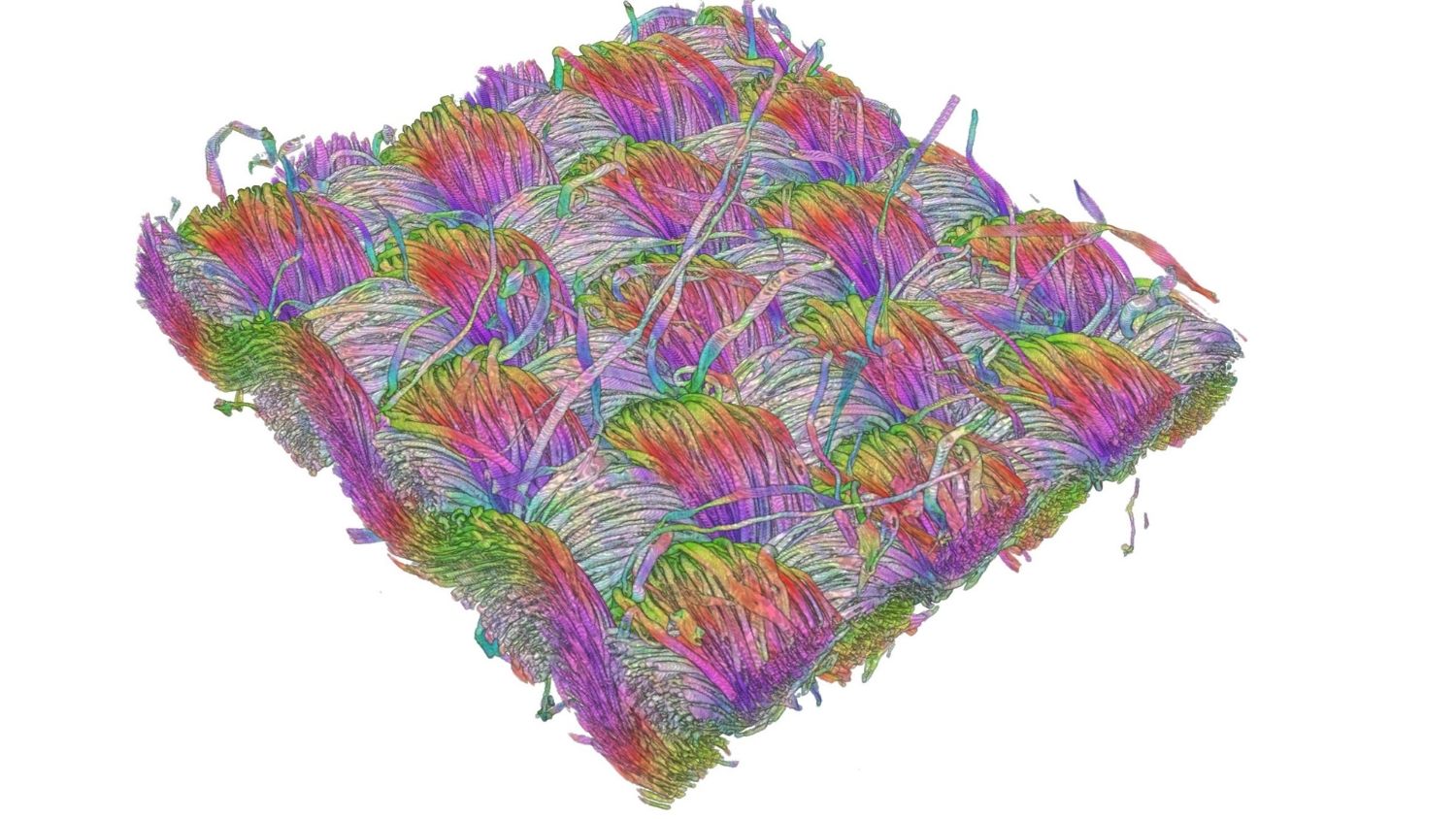

Then we sandwich the fabric between an artificial skin simulant at a certain pressure to press on all the fibers, and that gives us what the true contact area is on the surface. Then we take the image of that sandwich. The exerted pressure at the contact interface will change the fabric’s surface geometry, and that’s recorded by the instrument very precisely.

TA: How can you use an image to understand the friction of the fabric?

Mathur: Just by changing the fabric structure alone, we can change the frictional interaction with the skin. Why? Because different fabric surfaces create different interactions with our skin. Since we can’t see it with bare eyes, we used a CT scan to capture fabric images in a non-destructive way so we can see how the fabrics are contacting the skin, and investigate why the contact is different.

TA: What features of fabrics create its surface geometry?

Mathur: The selection of fibers and yarns, as well as the fabric structure, help tune the frictional property of textiles. For instance, you will see your cotton T-shirt feels different than your active wear, which is typically made from synthetic fibers.

In some applications, depending on the type of fiber used, there can be short fibers protruding from the fabric surface, known as fabric hairiness, which can lead to skin irritation. This instrument can tell us how much yarn hairiness there is when it starts to touch the camera.

Along with fibers, yarn and fabric structures also contribute to surface geometry and create different contact with the skin. In order to investigate these aspects, we are using the XRM-CT to capture the entire fabric dimensions, and quantify skin-fabric contact interface from the images, which will lead us to predict friction and abrasiveness of fabrics.

TA: In the study, you talked about how fabric is just one part of the equation for how comfortable fabric can feel – the other part is skin. How does your skin impact how abrasive fabric can feel?

Mathur: Skin properties definitely impact the feel of the fabrics. There are no two skin types that are exactly the same. That’s why we take fingerprints – because everyone has a unique identification. Everyone has a unique skin texture.

The other factors that also impact skin comfort are moisture content of the skin and temperature. For example, when the skin is moist, the fabric becomes stickier – it sticks to the skin and increases the friction. In terms of temperature, whether it’s hot or it’s cold, the way the body reacts to it is also different.

In our study, we accounted for different test conditions as well as the test environments. We would like to do a human study to confirm the findings from this research in a real setting at different humidity and pressure, and use surrogate skin to mimic healthy adult tissue and sweat conditions. What the industry is using right now is friction against a metal surface. What we need to know is: What is the friction against the skin?

- Categories: