Industry Expansion Solutions Leads Local Businesses to Success

From the mountains to the coast, NC State’s Industry Expansion Solutions (IES) helps North Carolina businesses face challenges head-on, offering deep, engineering-based expertise that sparks success. By training workers and guiding processes like management standards, additive manufacturing services, cybersecurity and more, IES helps these local businesses thrive.

The extension unit of NC State’s College of Engineering, IES is based on Centennial Campus — but its impact is felt throughout the state. Since 2000, IES’s manufacturing partnerships have added $2.9 billion to the North Carolina economy. This commitment to supporting businesses is core to Centennial Campus’ founding vision: to create a national model for public-private partnerships that drive economic development across North Carolina.

Babington Technology, based in Rocky Mount, makes equipment for the military and disaster relief. IES helped the company implement lean manufacturing processes, which aim to add value to customers and eliminate waste in every step of the manufacturing process. And by working with IES, the business has learned how to be more flexible in its specialized industry.

“The equipment that we make is very, very critical, but we’ve always been unique because our product is so special and different,” said Andy Babington, president of Babington Technology. “IES is teaching us how to adapt our products to other markets from an operational standpoint. They’re giving us a competitive advantage that’s critical to our future.”

For example, one client wanted reconfigured equipment for field kitchens because of the COVID-19 pandemic. What would have once taken Babington Technology a year to complete took eight weeks. “We’re able to respond to our clients when they have an emergency,” Babington said.

They’re giving us a competitive advantage that’s critical to our future.

A crucial part of IES’ work is ensuring businesses own their success. IES offers numerous courses, resources and training sessions throughout the state, and working with IES is a collaborative opportunity.

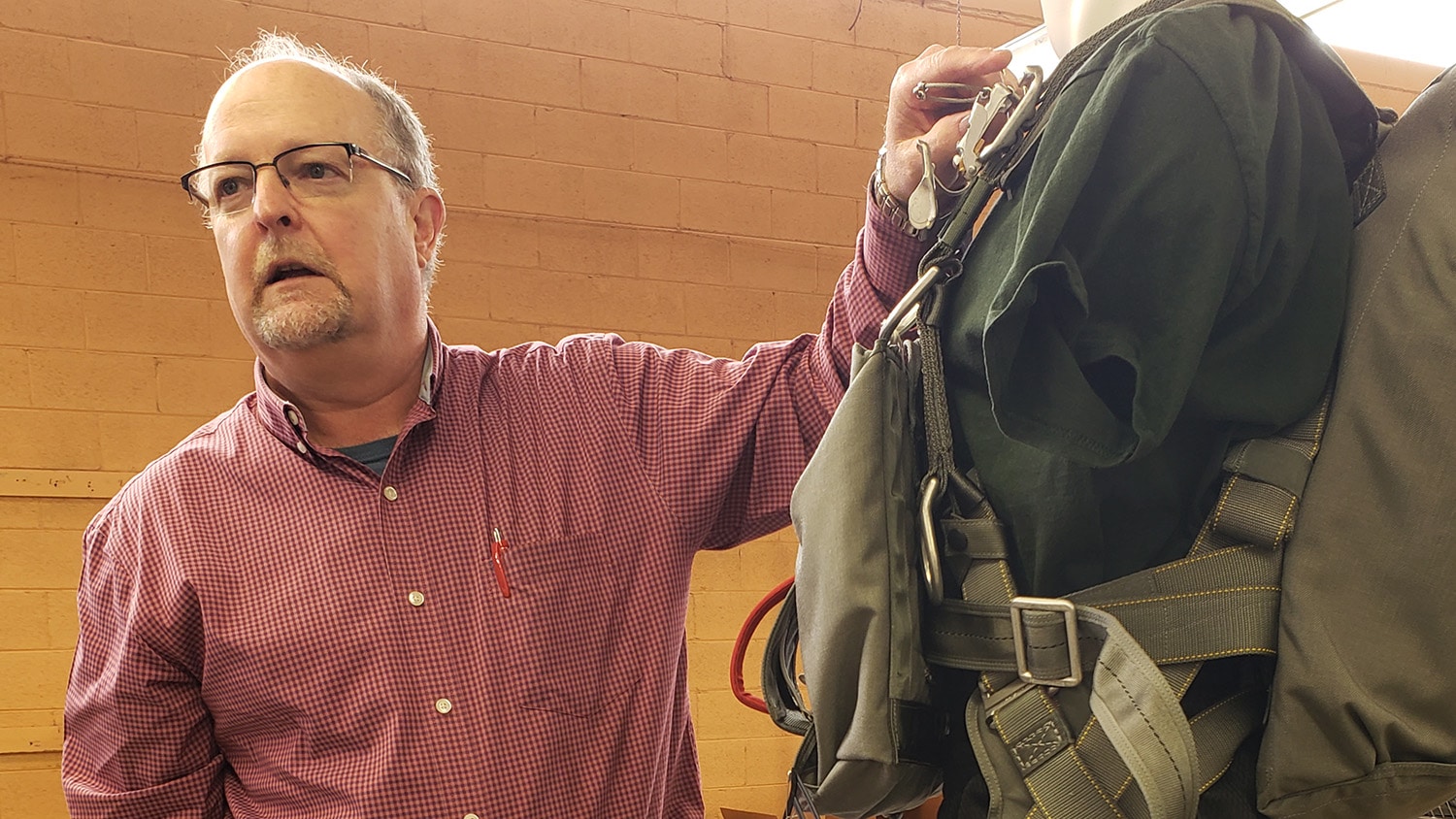

“IES does not come in and just do it for you,” said John Oswald, president of Mills Manufacturing, a military parachute manufacturer in Asheville. “They give you the training and support. They’re truly a partner.”

Mills Manufacturing serves the U.S. Army, Marine Corps, Navy, Air Force and Coast Guard, supplying airborne troop parachutes, cargo parachutes, extraction parachutes, deceleration parachutes and emergency parachutes. Mills had worked with IES to become ISO-certified and trained in lean manufacturing.

In 2014, the military parachute market started to shrink. Oswald wanted to find other industries that Mills’ specific skill set could cater to.

They give you the training and support. They’re truly a partner.

“We had been on our own looking to try to find other products we could make,” Oswald said. “We do highly specialized cut and sew, with heavy tapes and webbings, lighter nylons and hardware.”

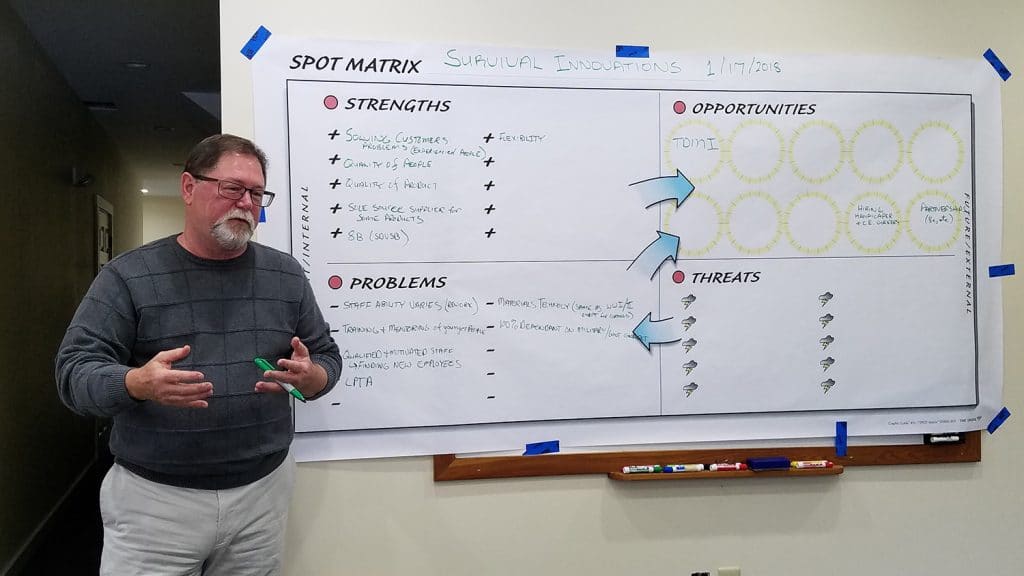

The company participated in IES’ Technology Driven Market Intelligence project to determine how to diversify its products and clientele. IES connected Mills with RTI International, which examined products that could be a good fit. RTI studied how saturated markets were with competitors, what cost structures were like and what end users needed.

“Ultimately, we never really connected on a product we were able to do that could help us diversify our business,” Oswald said. “But eliminating those products was as valuable as finding something we could do. We may have jumped in and started doing something without that research, and we would have gotten pretty far down the line before we realized it isn’t where we need to be.”

Working with IES has advanced Survival Innovations, too. The company, based in Mills River, North Carolina, designs and manufactures aviation life support equipment. Its skills include precision commercial sewing, programmable sewing, manual and automated material cutting as well as component assembly. IES has helped the company with cybersecurity and its AS9100 certification, which allows Survival Innovations to work in the U.S. Department of Defense aerospace sector.

“In the past four years, we’ve doubled in size, moved into a new facility, increased sales internationally, established commercial sales, and now we make our own hardware,” said general manager Mark Trexler. “The growth has been exponential with the help of IES.”

A key benefit to working with IES, Trexler said, is the ability to tap into its deep pool of resources at the university, government and industry level. “It’s not just all in-house knowledge,” Trexler said. “It’s a knowledge base.”

The growth has been exponential with the help of IES.

And that knowledge-sharing goes beyond IES’ expertise.

“IES has given us avenues to other parts of NC State, like the Wilson College of Textiles,” Trexler said. “It’s opened doors to things we never knew — different forms of manufacturing, other companies that can enhance what we do, other programs. We’re a team of 30 people. We don’t have time to go out and see everything that’s out there.”

These businesses are only some of the groups IES is working with through the Department of Defense’s Office of Local Defense Community Cooperation grant, including Mills, Survival, and Babington. And like NC State, Babington Technology, Survival Innovations and Mills Manufacturing three businesses are invested in North Carolina. Babington Technology is interested in working more with NC State, especially with its industrial engineering students. During the COVID-19 pandemic, Survival Innovations made personal protective equipment with the Carolina Textile District and employed local high-schoolers for help.

Oswald, of Mills Manufacturing, said the university’s dedication to the state is all the more reason to work with IES.

“Going with NC State is cost-effective, yes, but NC State also has an interest in businesses in our state and in our community,” Oswald said. “It’s all about strength in the state and community and businesses. That’s their motivation.”

- Categories: