For Immediate Release

An international team of researchers has discovered a new quantitative relation that allows for quick identification of promising material combinations for organic solar cells. The discovery could significantly reduce the “trial and error” aspect of solar cell production by reducing the time spent on finding the most efficient mixtures. The research appears in Nature Materials.

Presently, chemists working to design more efficient organic solar cells rely heavily on “post-mortem” or post-manufacture analysis of the distribution of the constituent materials of the cells they produce. In other words, if they want to see how the donor and acceptor molecules within the solar cell mix and interact, they must first create the mixture and produce samples that are examined on the molecular level. The high-performance solar cells we have now, for example, were created through a labor-intensive, trial-and-error approach of developing over 1,000 material combinations and looking at the optimal processing conditions for each one.

“Forces between molecules within a solar cell’s layers govern how much they will mix – if they are very interactive they will mix but if they are repulsive they won’t,” says Harald Ade, Goodnight Innovation Distinguished Professor of Physics at NC State and corresponding author of the paper. “Efficient solar cells are a delicate balance. If the domains mix too much or too little, the charges can’t separate or be harvested effectively. We know that attraction and repulsion depend on temperature, much like sugar dissolving in coffee – the saturation, or maximum mixing of the sugar with the coffee, improves as the temperature increases.”

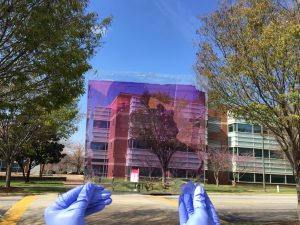

Ade, with postdoctoral researcher and first author Long Ye from NC State and chemist He Yan from the Hong Kong University of Science and Technology, set out to determine at what temperature these systems transform from two separate materials to one homogenous mixture in organic solar cells. Utilizing secondary ion mass spectrometry and X-ray microscopy, the team was able to look at molecular interactions at different temperatures to see when the phase change occurs. X-ray scattering allowed them to examine the purity of the domains. The end result was a parameter and quantitative model that describes domain mixing as a function of temperature and that can be used to evaluate different mixtures.

“We figured out the saturation level of the ‘sugar in the coffee’ as a function of temperature,” Ade says. “This parameter gives chemists the solubility limit of the system, which will enable them to determine which processing temperature will give optimum performance with the largest processing window.”

“In the past, people mainly studied this parameter in systems at room temperature using crude approximations. They couldn’t measure it with precision and at temperatures corresponding to processing conditions, which are much hotter,” says Ye. “The ability to measure and model this parameter will also offer valuable lessons about processing and not just material pairs. In principle, our method can do this for a given organic mixture at any temperature during the manufacturing process.”

“Currently chemists modify a molecule and use trials to see if it is a good material for solar cells, but if they have the wrong processing conditions they could miss a lot of good materials,” Ade says. “Our parameter measures the saturation level so they could determine whether the material system is good before they manufacture devices. Our ultimate goal is to form a framework and experimental basis on which chemical structural variation might be evaluated by simulations on the computer before laborious synthesis is attempted.”

Yan, associate professor at Hong Kong University of Science and Technology, is co-corresponding author. Co-authors include: Jean-Luc Bredas, Regents’ Professor of Chemistry from Georgia Tech; Hong Kong University of Science and Technology postdoctoral researcher Huawei Hu; NC State postdoctoral researcher Joo-Hyun Kim, and NC State graduate students Masoud Ghasemi and Joshua Carpenter. The work by NC State was supported by the U.S. Department of Energy (grant DE-FG02-98ER45737), the Office of Naval Research (grants N00141512322 and N000141712204) and a UNC General Administration Research Opportunity Initiative grant.

-peake-

Note to editors: An abstract follows.

“Quantitative relations between interaction parameter, miscibility and function in organic solar cells”

DOI: 10.1038/s41563-017-0005-1

Authors: Long Ye, Masoud Ghasemi, Brian A Collins, Joo-Hyun Kim, Joshua H. Carpenter, Terry McAfee and Harald Ade, North Carolina State University; Huawei Hu, Kui Jiang, Zhengke Li, Jingbo Zhao, Joshua Yuk Lin Lai, Tingxuan Ma and He Yan, Hong Kong University of Science and Technology; Tonghui Wang, Xiankai Chen and Jean-Luc Bredas, King Abdullah University of Science and Technology and Georgia Institute of Technology

Published: Nature Materials

Abstract:

Although it is known that molecular interactions govern morphology formation and purity of mixed domains of conjugated polymer donors and small-molecule acceptors, and thus largely control the achievable performance of organic solar cells, quantifying interaction-function relations has remained elusive. Here, we first determine the temperature-dependent effective amorphous-amorphous interaction parameter, χaa(T), by mapping out the phase diagram of a model amorphous polymer:fullerene material system. We then establish a quantitative “constant-kink-saturation” relation between χaa and the fill factor in organic solar cells that is verified in detail in a model system and delineated across numerous high- and low- performing materials systems, including fullerene and non-fullerene acceptors. Our experimental and computational data reveal that a high fill factor is obtained only when χaa is large enough to lead to strong phase separation. Our work outlines a basis for using various miscibility tests and future simulation methods that will significantly reduce or eliminate trial-and-error approaches to material synthesis and device fabrication of functional semiconducting blends and organic blends in general.

- Categories: