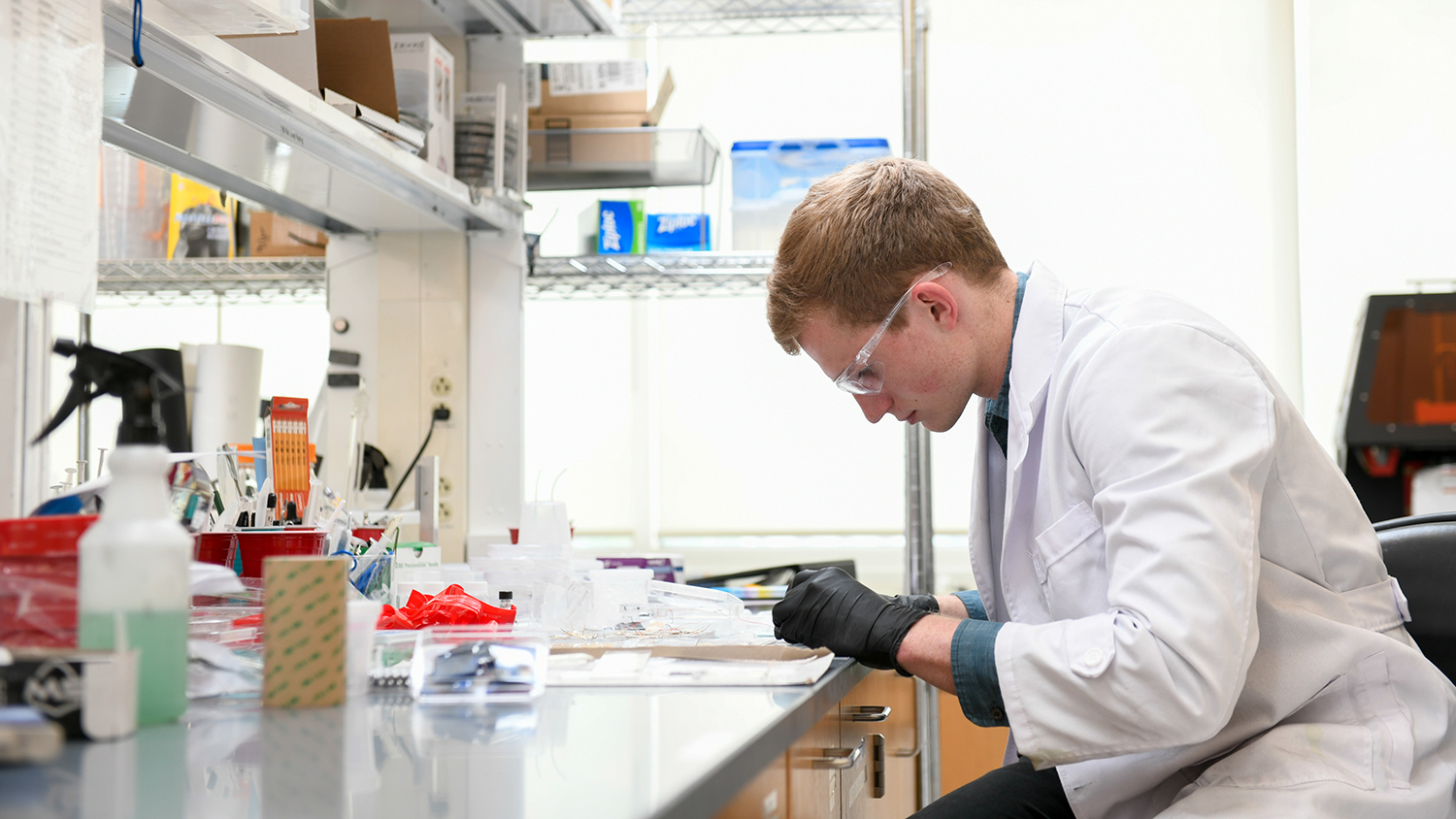

With applications in chemistry, engineering, physics and life sciences, soft materials are a transformative tool that spans research disciplines and industries.

Soft materials are squishable and moldable, and they often contain water. They have the ability to repair themselves, respond to stimuli and act as the building elements on which to grow coatings and other components. They can be used on foams, plastics, gels and more.

At NC State, research into soft material occurs in numerous colleges and departments. Here are some examples of the several projects our faculty have taken on.

Using Liquid Metal to Turn Motion into Electricity (Even Underwater)

A new soft, stretchable device converts movement into electricity and is able to work in wet environments. The heart of the energy harvester is a liquid metal alloy of gallium and indium. A hydrogel means the device could be used in biomedical settings, athletic wear and marine environments.

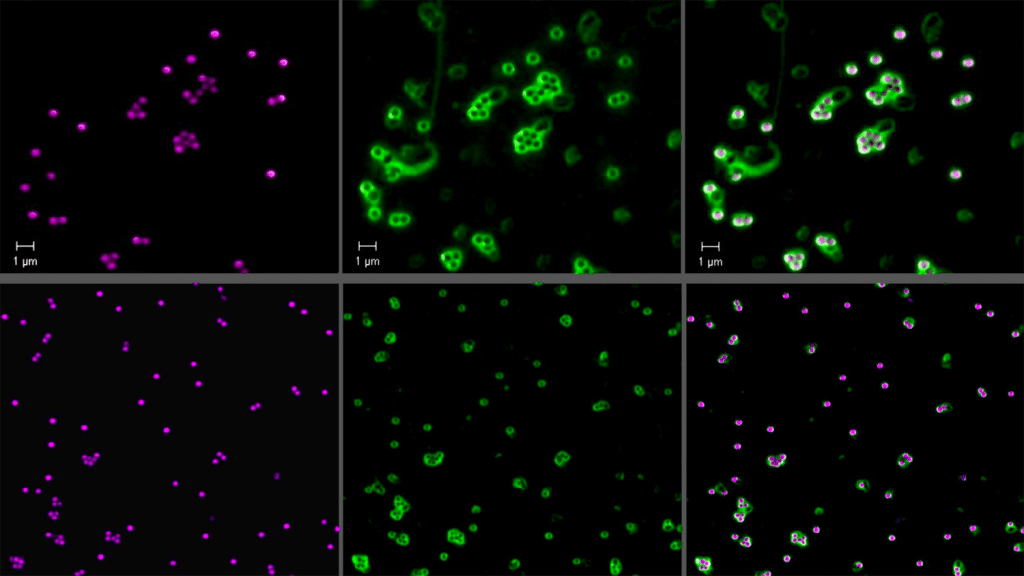

Combating Antibiotic Resistance by Preserving Biological Medicines

A soft material can preserve medicines capable of treating infections without the risk of antimicrobial resistance. NC State researchers developed new macromolecules that act as a glue around nanoparticle templates. This can stabilize therapeutic bacteriophages — viruses able to attack harmful bacteria in the body.

Turning Tree Residue Into Smart Hydrogels

Wood byproducts are turned into sensory hydrogels that can react to different stimuli, like temperature, pressure and moisture. Through advanced manufacturing methods, these hydrogels create smart materials that can be used in agriculture, health care and even veterinary medicine. Because they come from trees, the smart materials are biodegradable.

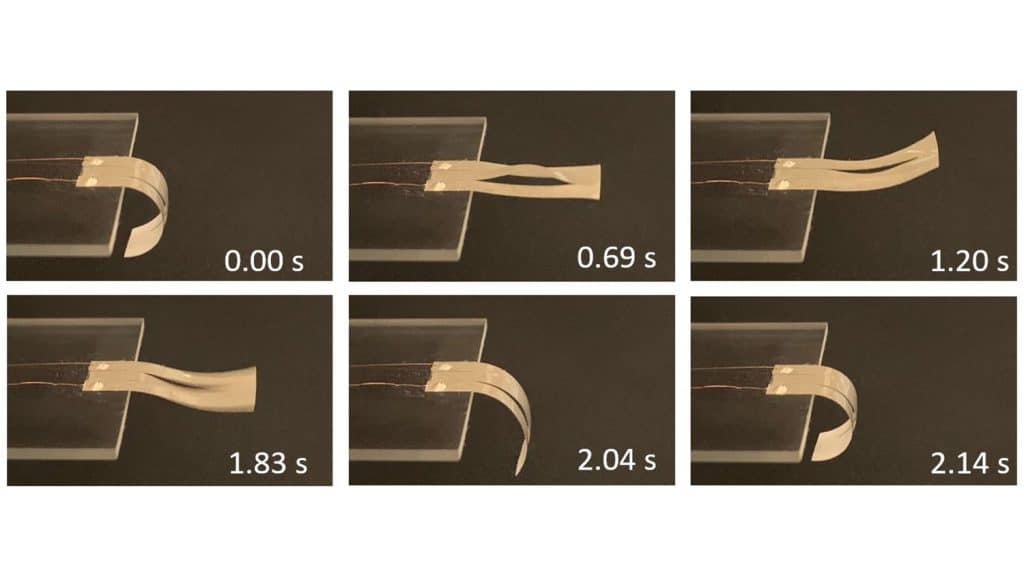

Accelerating Thermal Actuation for Soft Robotics

A new design for thermal actuators can create rapid movement in soft robotic devices. Actuators create motion by converting energy into work. Increased speed will benefit biomedical applications, prosthetic devices and high-end manufacturing.

Combining of Toughness and Stretchiness

New ionogels can dissipate a lot of energy when you deform them, making them very difficult to break. They’re also easy to make, easy to process and 3D-printable.