You Can Make Carbon Dioxide Filters With a 3D Printer

For Immediate Release

In a new study, North Carolina State University researchers demonstrated that it’s possible to make carbon dioxide capture filters using 3D printing. Specifically, they printed a hydrogel material that can hold carbonic anhydrase, an enzyme that speeds a reaction that turns carbon dioxide and water into bicarbonate.

The findings, published in the journal Gels, suggest 3D printing could be a faster, more versatile method of making filter designs.

“This manufacturing process, using 3D printing, makes everything faster and more precise,” said the study’s lead author Jialong Shen, assistant research professor of textile engineering, chemistry and science at NC State. “If you have access to a printer, and the raw materials, you can make this functional material.”

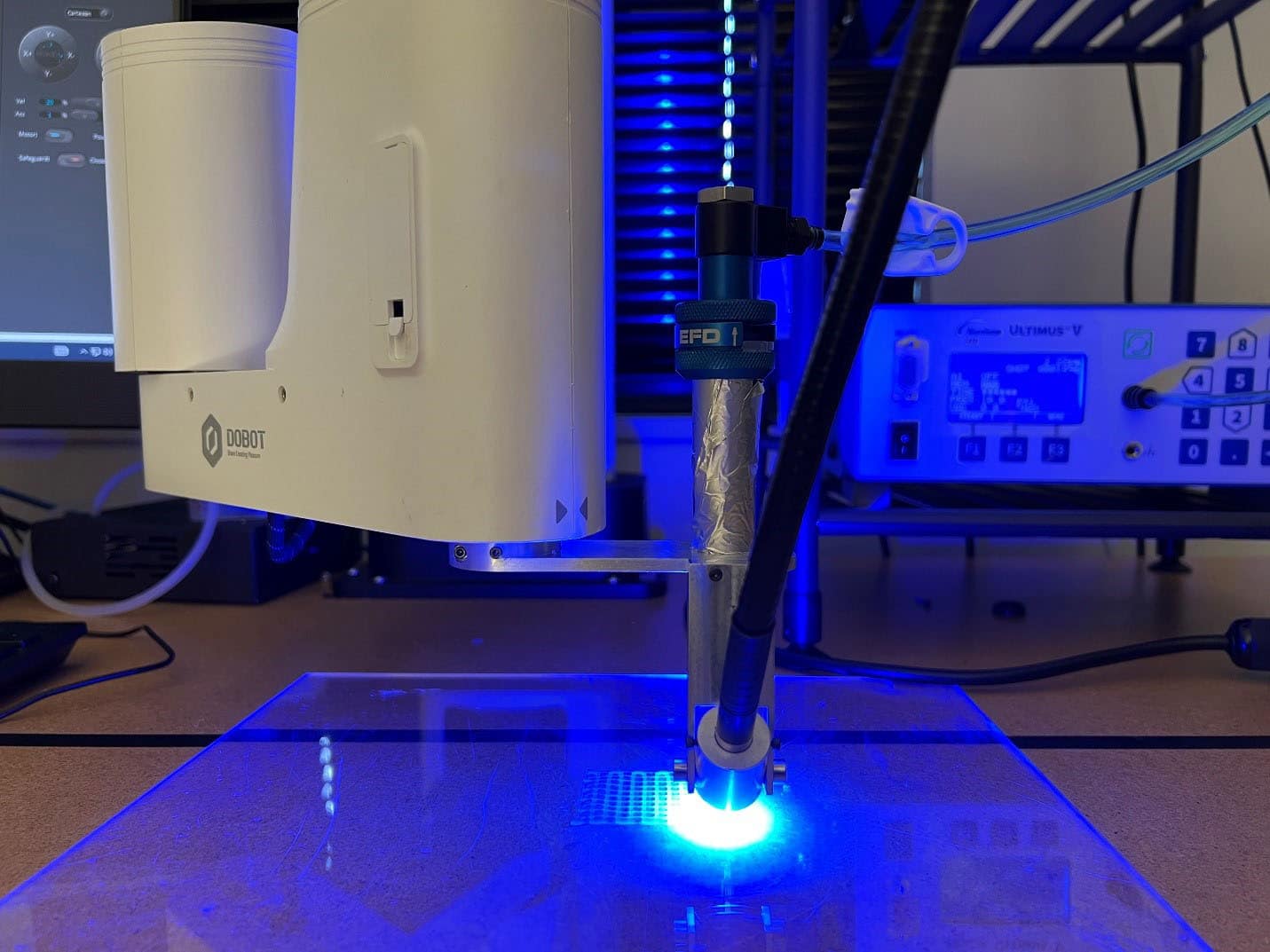

In the study, researchers in the NC State Wilson College of Textiles mixed a solution containing two different organic compounds – or the printing “ink” – and an enzyme called carbonic anhydrase. The researchers then printed thread-like filaments of the hydrogel into a two-dimensional grid while solidifying the solution with UV light as it was printed.

“We formulated the hydrogel in a way that would be mechanically strong enough to be 3D printed, and also extruded into a continuous filament,” Shen said. “The inspiration behind our design was our own cells, which have enzymes packed into compartmentalized spaces, filled with a fluid. That kind of environment is good for helping enzymes do their job.”

The researchers tested the properties of the material to understand how well it would bend and twist, and investigated the filter’s carbon capture performance. In a small-scale experiment, they found the filter captured 24% of the carbon dioxide in a gas mixture. While the capture rate is lower than what they’ve achieved in previous designs, the filter was less than an inch (2 centimeters) in diameter, and it could be made larger and in different modular shapes in order to stack them in a tall column. That could increase the capture efficiency, researchers said.

“In order to get a higher capture rate, we would need to make the filter larger in diameter, or stack more filters on top of each other,” Shen said. “We don’t think that’s an issue; this was an initial test at a small scale for ease of testing.”

The researchers also tested the filtration durability of the material, and found it retained 52% of its initial carbon capture performance after more than 1,000 hours.

“This work is still early stage, but our findings suggest there are new ways to make materials for carbon capture devices,” said the study’s co-corresponding author Sonja Salmon, associate professor of textile engineering, chemistry and science at NC State. “We’re offering hope for carbon capture.”

The study, “Carbonic Anhydrase Enhanced UV-Crosslinked PEG-DA/PEO Extruded Hydrogel Flexible Filaments and Durable Grids for CO₂ Capture,” was published online in Gels. Co-authors included Sen Zhang and Xiaomeng Fang. Funding was provided by North Carolina State University, the Novo Nordisk Foundation, and the Alliance for Sustainable Energy, LLC, Managing and Operating Contractor for the National Renewable Energy Laboratory for the U.S. Department of Energy.

-oleniacz-

Note to Editors: The study abstract follows.

Carbonic Anhydrase Enhanced UV-Crosslinked PEG-DA/PEO Extruded Hydrogel Flexible Filaments and Durable Grids for CO₂ Capture

Authors: Jialong Shen, Sen Zhang, Xiaomeng Fang and Sonja Salmon

Published: April 16, 2023, Gels

DOI: 10.3390/gels9040341

Abstract: In this study, poly (ethylene glycol) diacrylate/poly (ethylene oxide) (PEG-DA/PEO) interpenetrating polymer network hydrogels (IPNH) were extruded into 1D filaments and 2D grids. The suitability of this system for enzyme immobilization and CO2 capture application was validated. IPNH chemical composition was verified spectroscopically using FTIR. The extruded filament had an average tensile strength of 6.5 MPa and elongation at break of 80%. IPNH filament can be twisted and bent and therefore is suitable for further processing using conventional textile fabrication methods. Initial activity recovery of the entrapped carbonic anhydrase (CA) calculated from esterase activity, showed a decrease with an increase in enzyme dose, while activity retention of high enzyme dose samples was over 87% after 150 days of repeated washing and testing. IPNH 2D grids that were assembled into spiral roll structured packings exhibited increased CO2 capture efficiency with increasing enzyme dose. Long-term CO2 capture performance of the CA immobilized IPNH structured packing was tested in a continuous solvent recirculation experiment for 1032 h, where 52% of the initial CO2 capture performance and 34% of the enzyme contribution were retained. These results demonstrate the feasibility of using rapid UV-crosslinking to form enzyme-immobilized hydrogels by a geometrically-controllable extrusion process that uses analogous linear polymers for both viscosity enhancement and chain entanglement purposes, and achieves high activity retention and performance stability of the immobilized CA. Potential uses for this system extend to 3D printing inks and enzyme immobilization matrices for such diverse applications as biocatalytic reactors and biosensor fabrication.