TPACC Marks 30 Years of Innovating and Adapting to Meet the Needs of Government, Industry Partners

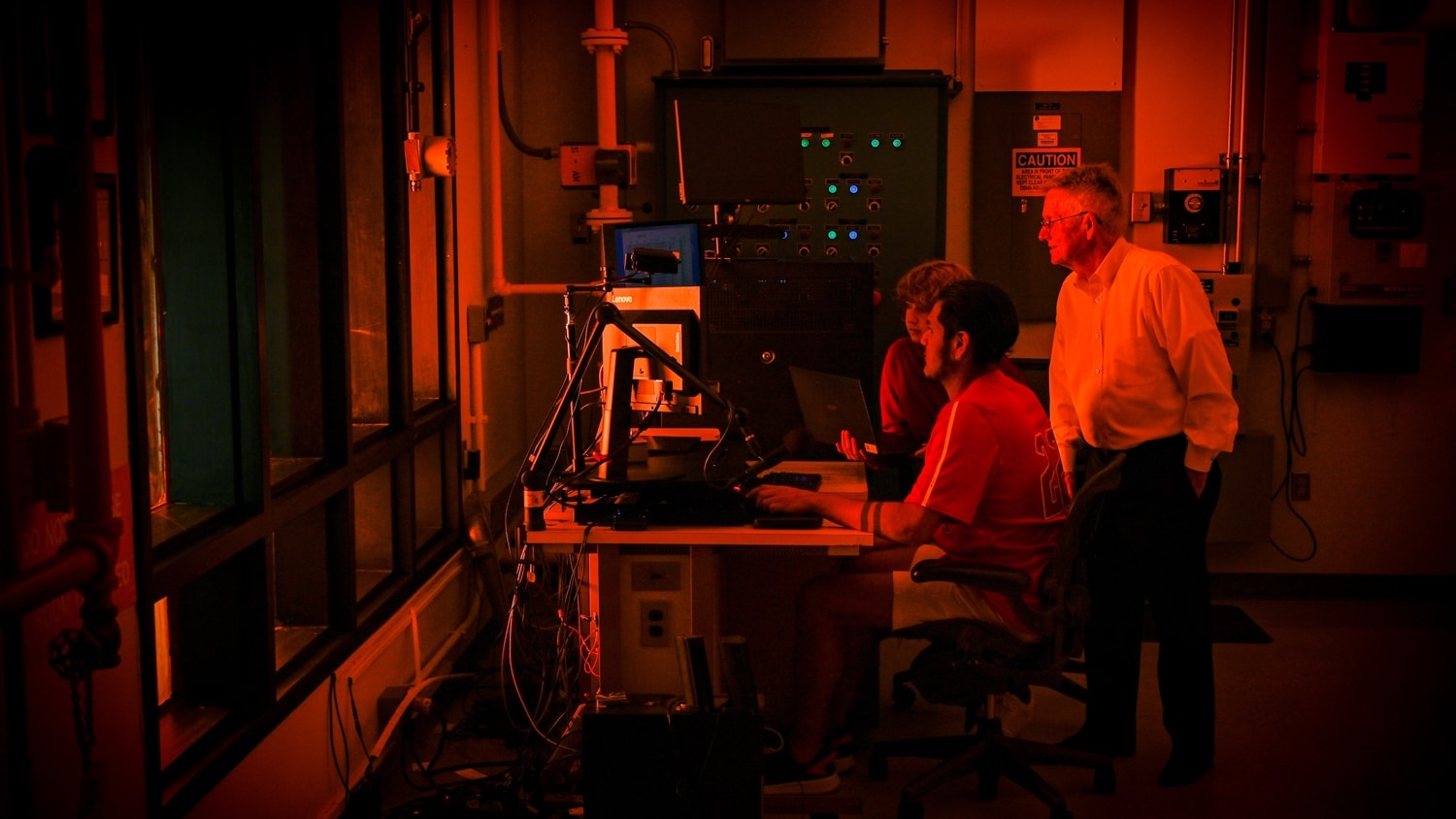

For Wilson College of Textiles Professor Roger Barker, walking into the Textile Protection and Comfort Center (TPACC) on NC State’s Centennial Campus is something of a full-circle moment in 2024.

He finds reflection in watching teams develop new, cutting-edge ways to prevent heat strain in members of the Armed Forces … or in seeing researchers workshop test methods that might be the silver bullet for preventing cancer among firefighters … or, in collaborating with a major clothing retailer hoping to validate their claims about a new type of athletic wear.

“I’m amazed,” Barker says. “I think the vision that I had for TPACC at the beginning has been realized, over and over. And it didn’t occur overnight.”

It’s a poignant assessment of the center Barker once founded — which is now set to celebrate 30 years operating at the crossroads of academia, government and industry in a way no other institutions do.

“We’ve always known that we’re kind of a unique institution: a center within an academic setting,” Barker says. “You can find several of the things we do at different locations around the world. But you won’t find all of it, like we have here, anywhere else.”

Adapting over 30 years

The fact that TPACC boasts such a multi-faceted array of capabilities is, in many ways, a product of its growth over the last three decades — a trajectory defined by adaptability.

In the early 1990s, the center largely grew out of Barker’s vision for a one-stop location that would marry his research into the push-and-pull of heat protection and comfort, recognizing the two go hand-in-hand; after all, a firefighter who forgoes some of their protective gear because it’s uncomfortable faces a direct threat to their safety.

But if TPACC’s work protecting firefighters from flames and smoke was cutting edge in the late 20th century, it took on increased meaning following the September 11, 2001 terrorist attacks, which exposed the need for more robust chemical protections for first responders.

TPACC was among the first institutions to receive grant funding from the U.S. Department of Homeland Security (DHS), itself created in the wake of 9/11. The mission: to develop more user-friendly turnout suits for firefighters that would provide better protection not just from fires, but from chemical vapors and particles, too.

The center would later receive further DHS funding for what would become its Man-In-Simulant-Test, or MIST, facility, which helps TPACC researchers evaluate how toxic vapors can permeate garments.

TPACC has also been at the heart of cutting-edge research developing suits to protect servicemembers from chemical exposures and improvised explosive devices (IEDs), research born from casualties sustained during U.S. involvement in Iraq.

“We were already on the map,” recalls Shawn Deaton, TPACC deputy director. “But our purpose took on new meaning following 9/11, and with our subsequent military involvement overseas. It led to TPACC acquiring a lot more testing capabilities, and increasing our research as it relates to protective clothing.”

Over the decades, the center has continually adapted with the help of new technologies. Its PyroMan manikin (more recently “upgraded” with the new Dynamic PyroMan) has proved integral to testing the durability and protective properties of thermal protective gear — critical garments to protect firefighters, members of the Armed Forces and industry workers facing potential heat exposures.

Whatever the endeavor, TPACC’s prowess helps equip industry and government partners with reliable, science-based data — not just on a single swatch or garment, but for full ensemble systems worn by first responders.

And it’s a mission that resonates with every test or reading conducted by the dedicated scientists at the Centennial Campus facility.

“We think we have a mission that extends beyond the walls of the university,” Barker marvels. “It’s so dear to our hearts in TPACC.”

A valuable asset for industry partners

TPACC’s focus on how a garment or “ensemble” fares under the stress of fire, heat or human movement has brought the center plenty of valuable partnerships beyond the front lines, too.

Companies regularly harness the expertise of the Wilson College of Textiles in developing and improving cutting-edge apparel and gear.

“It’s been great to work with all the partners that we have. Without them, we don’t exist. We’re a self supporting institution,” Deaton points out. “It is critical, and with their advancements and them using us to evaluate or help improve their products, it certainly helps us out as well.”

That symbiotic relationship has proven useful for companies in search of science-based conclusions to test their products, workshopped through test methods TPACC researchers regularly develop through the center’s deep ties to internationally-recognized standards organizations like ASTM, the National Fire Protection Association, the American Association of Textile Chemists and Colorists and the International Organization for Standardization.

Wilson College Dean David Hinks specifically cites TPACC’s early-century research support for Under Armour, at the time a young company, as a key factor in the company becoming a force in the athletic wear industry — today worth some $2.85 billion.

“While TPACC is internationally renowned for its work in protecting and saving lives, its research is equally relevant to areas of functional garments such as sports apparel,” Hinks points out.

It’s also merely one example of the cutting edge research happening on NC State’s Centennial Campus, where researchers come together with industry partners to foster innovation.

To that end, TPACC is a big factor, Hinks adds, in the university routinely ranking among the nation’s best in all metrics of innovation, from accumulating patents to launching startup companies.

“TPACC is a major contributor to not only the education and research inside Wilson College, but also the innovation that is the translation of creative ideas into commercial success,” Hinks notes, while staying true to perhaps the center’s most solemn purpose:

“In the case of TPACC,” Hinks says, “that commercial success, at its core, is about saving lives.”

Staying true to its core mission

But even as TPACC has showcased its versatility in collaborating with companies across the commercial spectrum, its focus on the health of firefighters and members of the Armed Forces has remained central to its mission — albeit with an adapting focus as needs change.

For instance, in recent years, research teams have honed in on so-called “forever chemicals” in developing fire protective equipment aimed not just at protecting firefighters from heat — but from carcinogens, too.

Today, no facility in the U.S. conducts vapor protective suit testing at the level TPACC does.

The center’s research has led to innovative firefighting suits now worn by multiple fire departments — including some close to home, in NC State’s Research Triangle region.

The significance of that work is never lost on the team — particularly with the firefighting industry, in recent years, having been identified by the Centers for Disease Control as a known cancer risk.

“When you’re looking at it from the standpoint of firefighters and the epidemic of cancer that they have, anything we can do to lessen that is critical,” says Wilson College assistant professor Bryan Ormond, a TPACC researcher with extensive work in the realm of fire protection, dating back two decades.

“If it’s one firefighter’s family that doesn’t have to hear that diagnosis,” Ormond adds, “Everything that we’ve done has been worth it.”

The next 30 years

What do the next 30 years have in store for TPACC?

Climate change will surely be a big part of the center’s future.

After all, the likelihood of more wildfires will likely only underscore the need for equipment that protects firefighters from heat and cancer risks — while simultaneously being functional enough to avoid the dangers of heat stroke on a warming planet.

To that end, a warmer climate may also only heighten the interest among industry partners in developing cutting-edge clothing that keeps the consumer cool in their day-to-day life.

“Most of the time when you’re looking at the effects of comfort on clothing you’re looking at temperature and humidity,” Deaton points out.

That may well call for new and emerging technology to aid TPACC researchers, Barker adds.

“We see a real role for TPACC that involves new-generation, instrumented manikins that are better able to operate at temperatures that are above normal,” he says.

Beyond that? It’s hard to get much more specific. After all, if there’s been one constant over the past 30 years, it’s been the ability of Barker and his team to adapt and respond in the wake of major global events.

“It’s all driven by what’s happening,” he says. “What we’ve found is that we have to keep changing and evolving based on that need. There are always new hazards that are coming up. That’s why the research has such a ring of currency to it. It’s because we’re responding.“

This post was originally published in Wilson College of Textiles News.

- Categories: