How Electric Fields Could Change Ceramics

We reported last year on research showing that applying an electric field can result in stronger ceramic materials – and a cheaper, more energy-efficient manufacturing process. A new paper helps us understand why that happens – and what the limitations are. As an added bonus, researchers have also figured out a new, easier way to determine the energy associated with defects in ceramic materials.

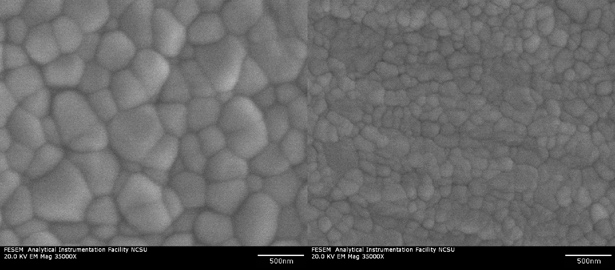

Experimenting with a ceramic material called yttria-stabilized zirconia (3Y-TZP), materials researcher Hans Conrad has found that electric fields improve manufacturing processes and result in a stronger finished product – until the field reaches 30 volts per centimeter (V/cm). At least Conrad found that increasing the voltage from 30 V/cm to 50 V/cm, resulted in no further effect. Conrad focused on 3Y-TZP because it is used in a wide array of applications, from sensors to fuel cells.

The electric field makes it easier to work with ceramic materials because it wipes out the energy associated with grain boundary defects. A grain boundary defect occurs when atoms from one crystal are not in alignment with the atoms in an adjacent crystal. The interaction of the electrons of these non-aligned atoms creates an electric charge – and these “space charges” create the grain boundary energy. When scientists introduce an electric field, it interacts with that grain boundary energy, leading to reduced sintering temperatures, easier deformation of the material and a smaller grain size in the finished product (which makes it stronger).

Allow me to illustrate how big a difference an electric field can make. Sintering is the process of exposing ceramic powders to high heat in order to fuse them together and make them non-porous. Traditionally, 3Y-TZP is sintered at approximately 1,500 degrees Celsius and results in a ceramic with grains measuring around 360 nanometers (nm) in diameter. If you apply a 60 Hertz AC field at 13.9 V/cm, the porosity is eliminated at 1,250 degrees Celsius, with grains around 134 nm in diameter (and remember – smaller grains are better). The 2010 paper on sintering is available here.

Conrad’s new paper also outlines a new means of calculating the grain boundary energy and space charge of ceramic materials by determining how the material responds in the presence of an electric field. The new method is significantly easier and less expensive than traditional techniques. That’s important, because if you want to improve ceramics, you need to change manufacturing processes and materials to reduce the grain boundary energy – and now it will be cheaper and easier to determine the grain boundary energy.

While Conrad has shown what can be done using electric fields with 3Y-TZP, his research team is currently working to see what effect the fields have on magnesium oxide, aluminum oxide and other ceramics. Conrad’s team is also working to uncover, quantitatively, how the electric field interacts with the grain boundary at an atomic level.

A paper on the work, “Space Charge and Grain Boundary Energy in Zirconia (3Y-TZP)” is forthcoming from the Journal of the American Ceramic Society.The work in the Journal of the American Ceramic Society paper was funded by the National Science Foundation.

- Categories: