Researchers Find New Phase of Carbon, Make Diamond at Room Temperature

For Immediate Release

Researchers from North Carolina State University have discovered a new phase of solid carbon, called Q-carbon, which is distinct from the known phases of graphite and diamond. They have also developed a technique for using Q-carbon to make diamond-related structures at room temperature and at ambient atmospheric pressure in air.

Phases are distinct forms of the same material. Graphite is one of the solid phases of carbon; diamond is another.

“We’ve now created a third solid phase of carbon,” says Jay Narayan, the John C. Fan Distinguished Chair Professor of Materials Science and Engineering at NC State and lead author of three papers describing the work. “The only place it may be found in the natural world would be possibly in the core of some planets.”

Q-carbon has some unusual characteristics. For one thing, it is ferromagnetic – which other solid forms of carbon are not.

“We didn’t even think that was possible,” Narayan says.

In addition, Q-carbon is harder than diamond, and glows when exposed to even low levels of energy.

“Q-carbon’s strength and low work-function – its willingness to release electrons – make it very promising for developing new electronic display technologies,” Narayan says.

But Q-carbon can also be used to create a variety of single-crystal diamond objects. To understand that, you have to understand the process for creating Q-carbon.

Researchers start with a substrate, such as such as sapphire, glass or a plastic polymer. The substrate is then coated with amorphous carbon – elemental carbon that, unlike graphite or diamond, does not have a regular, well-defined crystalline structure. The carbon is then hit with a single laser pulse lasting approximately 200 nanoseconds. During this pulse, the temperature of the carbon is raised to 4,000 Kelvin (or around 3,727 degrees Celsius) and then rapidly cooled. This operation takes place at one atmosphere – the same pressure as the surrounding air.

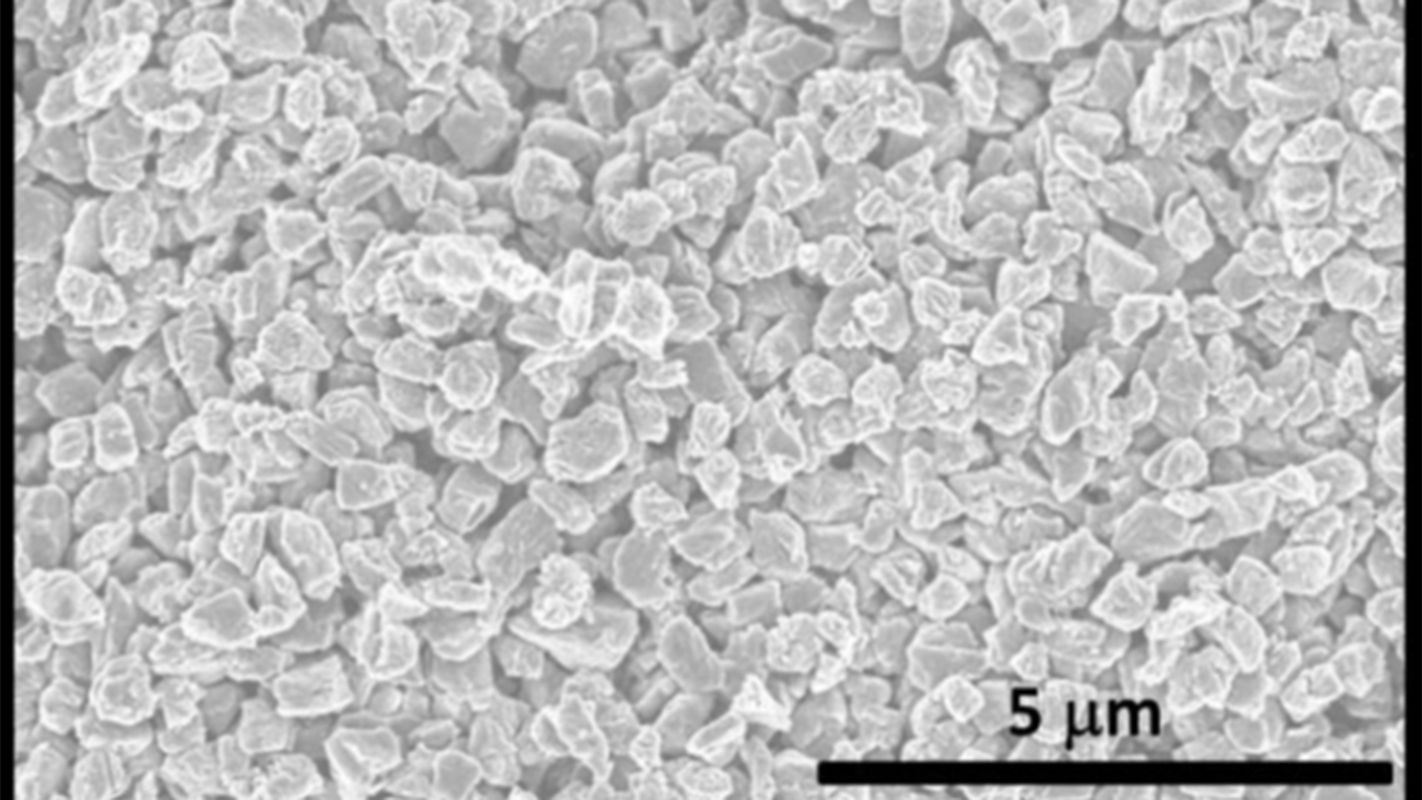

The end result is a film of Q-carbon, and researchers can control the process to make films between 20 nanometers and 500 nanometers thick.

By using different substrates and changing the duration of the laser pulse, the researchers can also control how quickly the carbon cools. By changing the rate of cooling, they are able to create diamond structures within the Q-carbon.

“We can create diamond nanoneedles or microneedles, nanodots, or large-area diamond films, with applications for drug delivery, industrial processes and for creating high-temperature switches and power electronics,” Narayan says. “These diamond objects have a single-crystalline structure, making them stronger than polycrystalline materials. And it is all done at room temperature and at ambient atmosphere – we’re basically using a laser like the ones used for laser eye surgery. So, not only does this allow us to develop new applications, but the process itself is relatively inexpensive.”

And, if researchers want to convert more of the Q-carbon to diamond, they can simply repeat the laser-pulse/cooling process.

If Q-carbon is harder than diamond, why would someone want to make diamond nanodots instead of Q-carbon ones? Because we still have a lot to learn about this new material.

“We can make Q-carbon films, and we’re learning its properties, but we are still in the early stages of understanding how to manipulate it,” Narayan says. “We know a lot about diamond, so we can make diamond nanodots. We don’t yet know how to make Q-carbon nanodots or microneedles. That’s something we’re working on.”

NC State has filed two provisional patents on the Q-carbon and diamond creation techniques.

The work is described in two papers, both of which were co-authored by NC State Ph.D. student Anagh Bhaumik. “Novel Phase of Carbon, Ferromagnetism and Conversion into Diamond” was published online Dec. 2 in the Journal of Applied Physics. “Direct conversion of amorphous carbon into diamond at ambient pressures and temperatures in air” was published Oct. 7 in the journal APL Materials. The work was supported in part by the National Science Foundation, under grant number DMR-1304607.

-shipman-

Note to Editors: The study abstracts follow.

“Novel Phase of Carbon, Ferromagnetism and Conversion into Diamond”

Authors: Jagdish Narayan and Anagh Bhaumik, North Carolina State University

Published: Nov. 30, Journal of Applied Physics

DOI: 10.1063/1.4936595

Abstract: We report the discovery of new phase of carbon (referred to as Q-carbon) and address fundamental issues related to direct conversion of carbon into diamond at ambient temperatures and pressures in air without any need for catalyst and presence of hydrogen. The Q-carbon is formed as result of quenching from super undercooled state by using high-power nanosecond laser pulses. We discuss the equilibrium phase diagram (P vs. T) of carbon, and show that by rapid quenching kinetics can shift thermodynamic graphite/diamond/ liquid carbon triple point from 5000K/12GPa to super undercooled carbon at atmospheric pressure in air. It is shown that nanosecond laser heating of diamondlike amorphous carbon on sapphire, glass and polymer substrates can be confined to melt carbon in a super undercooled state. By quenching the carbon from the super undercooled state, we have created a new state of carbon (Q-carbon) from which nanodiamond, microdiamond, microneedles and thin films are formed depending upon the nucleation and growth times allowed for diamond formation. The Q-carbon quenched from liquid is a new state of solid carbon with a higher mass density than amorphous carbon and a mixture of mostly four-fold sp3 (75-85%) and the rest three-fold sp2 bonded carbon (with distinct entropy). It is expected to have new and improved mechanical hardness, electrical conductivity, chemical and physical properties, including room-temperature ferromagnetism (RTFM) and enhanced field emission. Here we present interesting results on RTFM, enhanced electrical conductivity, and surface potential of Q-carbon to emphasize its unique properties. The Q-carbon exhibits robust bulk ferromagnetism with estimated Curie temperature of about 500K and saturation magnetization value of 20 emu g-1. From the Q-carbon, diamond phase is nucleated and a variety of micro- and nanostructures, and large-area single-crystal diamond sheets are grown by allowing growth times as needed. Subsequent laser pulses can be used to grow nanodiamond into microdiamond and nucleate other nanostructures of diamond on the top of existing microdiamond and create novel nanostructured materials. The microstructural details provide insights into the mechanism of nanodiamond and microdiamond formation. This process allows carbon to diamond conversion and formation of useful nanostructures and microstructures at ambient temperatures in air at atmospheric pressure on practical and heat-sensitive substrates in a controlled way without need for any catalysts and hydrogen to stabilize sp3 bonding for diamond formation.

“Direct conversion of amorphous carbon into diamond at ambient pressures and temperatures in air”

Authors: Jagdish Narayan and Anagh Bhaumik, North Carolina State University

Published: Oct. 7, APL Materials

DOI: 10.1063/1.4932622

Abstract: We report on fundamental discovery of conversion of amorphous carbon into diamond by irradiating amorphous carbon films with nanosecond lasers at room-temperature in air at atmospheric pressure. We can create diamond in the form of nanodiamond (size range <100 nm) and microdiamond (>100 nm). Nanosecond laser pulses are used to melt amorphous diamondlike carbon and create a highly undercooled state, from which various forms of diamond can be formed upon cooling. The quenching from the super undercooled state results in nucleation of nanodiamond. It is found that microdiamonds grow out of highly undercooled state of carbon, with nanodiamond acting as seed crystals.

- Categories: