New ‘Bottlebrush’ Electroactive Polymers Make Dielectric Elastomers Increasingly Viable for Use in Devices

For Immediate Release

A multi-institutional research team has developed a new electroactive polymer material that can change shape and size when exposed to a relatively small electric field. The advance overcomes two longstanding challenges regarding the use of electroactive polymers to develop new devices, opening the door to a suite of applications ranging from microrobotics to designer haptic, optic, microfluidic and wearable technologies. The work was performed by researchers at North Carolina State University, the University of North Carolina at Chapel Hill, Carnegie Mellon University and the University of Akron.

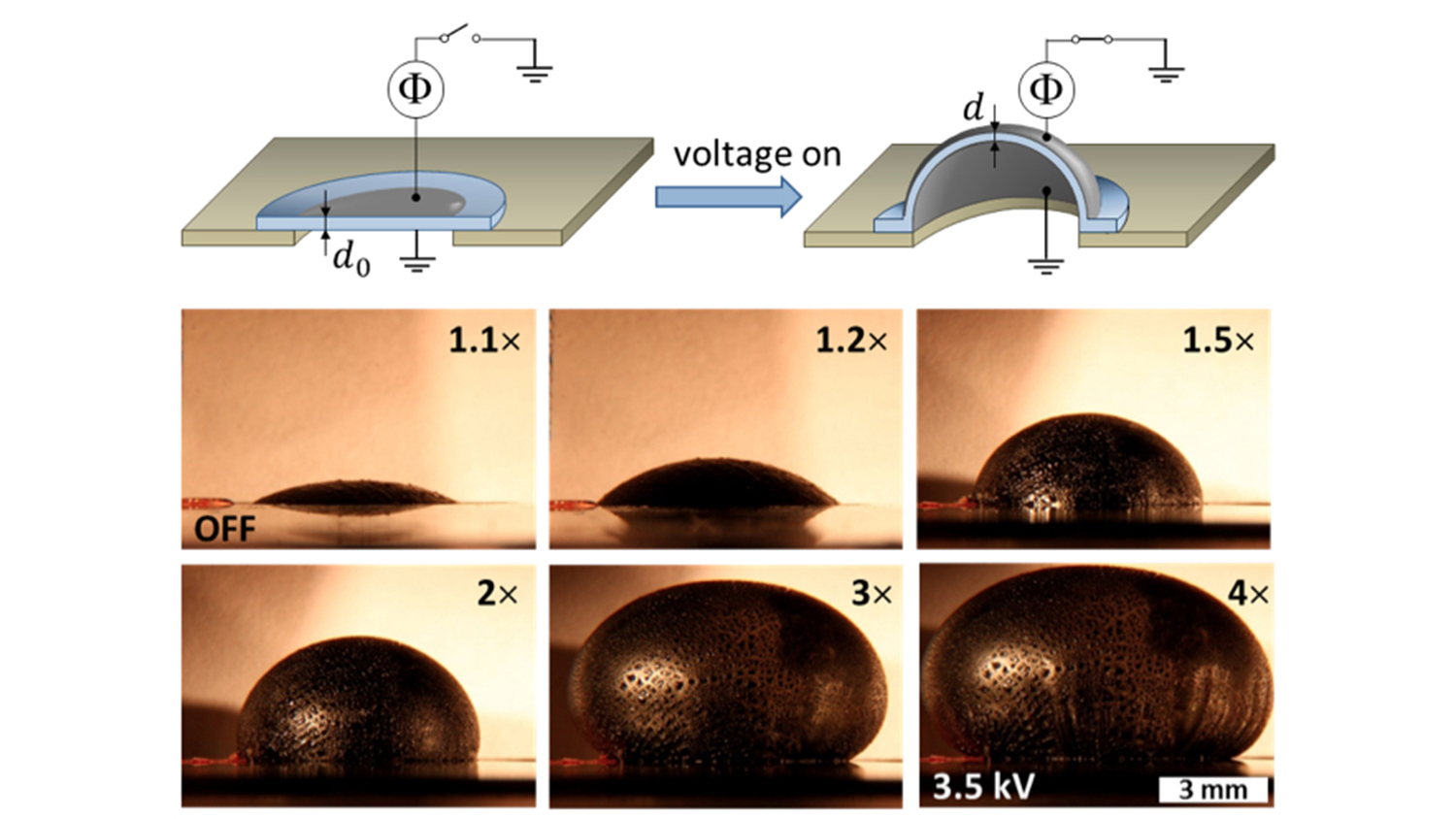

“Dielectric elastomers are the most responsive electroactive polymers in terms of achievable strains, but two big hurdles have effectively prevented the smart materials community from using them in commercial devices,” says Richard J. Spontak, Distinguished Professor of Chemical and Biomolecular Engineering and professor of materials science and engineering at NC State, who co-authored a paper describing the new materials. “First, previous dielectric elastomers required large electric fields in order to trigger actuation, or movement – on the order of at least 100 kilovolts per millimeter (kV/mm). With our new material, we can see actuation at levels as low as ca. 10 kV/mm.”

“The second challenge is that, previously, materials had to be pre-strained,” Spontak says. “This would either mean using a frame to physically strain the material, or adding a second component to the polymer to retain the strain after it was applied. But our material consists of a single component that is specifically designed at the molecular level to inherently possess pre-strain. In other words, we don’t need a frame or a second component – our material is ready to be used as soon as it is cross-linked into a specific shape.”

The new material that has permitted this breakthrough is a “bottlebrush” silicone elastomer, which has been engineered to possess these unique properties, and it is not difficult to manufacture.

“We are working specifically with bottlebrush polymers, which are prepared by grafting long polymeric side chains to a polymer backbone,” says Sergei S. Sheiko, George A. Bush, Jr. Distinguished Professor of Chemistry at UNC and corresponding author of the paper. “The resulting molecules may be viewed as filaments that are thick, yet remain quite flexible, which allows for significant reduction of the materials’ rigidity and makes them more stretchable. Furthermore, the mechanical properties can be controlled by varying the bottlebrush architecture – for example, by preparing molecules with different degrees of polymerization of grafted chains and different grafting densities.

“This architectural control of mechanical properties has reduced the limit of stiffness in dry polymer materials by 1,000 times, demonstrated extensibility of up to eight times, and opened up new applications not available to stiffer materials or materials with liquid fractions,” Sheiko says. “One of these applications – their use as free-standing dielectric elastomers – has been demonstrated, which we discuss in this paper.”

“We’re at the earliest stages of identifying all the potential ways in which we could use this new class of material,” Spontak says. “It works better than anticipated, and now we’re beginning to consider potential applications.”

The paper, “Bottlebrush Elastomers: A New Platform for Freestanding Electroactuation,” is published in the journal Advanced Materials. Lead author of the paper is Mohammad Vatankhah-Varnoosfaderani, a postdoctoral researcher at UNC. The paper was co-authored by William F. M. Daniel, Alexandr P. Zhushma, Qiaoxi Li and Benjamin J. Morgan of UNC; Daniel P. Armstrong of NC State; Krzysztof Matyjaszewski of Carnegie Mellon; and Andrey V. Dobrynin of the University of Akron. The work was done with support from the National Science Foundation under grants DMR 1122483, DMR 1407645, DMR 1436201 and DMR 1409710, and from Becton Dickinson Technologies.

-shipman-

Note to Editors: The study abstract follows.

“Bottlebrush Elastomers: A New Platform for Freestanding Electroactuation”

Authors: Mohammad Vatankhah-Varnoosfaderani, William F. M. Daniel, Alexandr P. Zhushma, Qiaoxi Li, Benjamin J. Morgan and Sergei S. Sheiko, University of North Carolina, Chapel Hill; Krzysztof Matyjaszewski, Carnegie Mellon University; Daniel P. Armstrong and Richard J. Spontak, North Carolina State University; Andrey V. Dobrynin, University of Akron

Published: Nov. 8, Advanced Materials

DOI: 10.1002/adma.201604209

Abstract: Dielectric elastomers (DEs) are the leading technology for artificial muscles due to a favorable combination of large stroke, fast response, and high energy density. However, at large actuations, DEs are prone to spontaneous rupture from electromechanical instability. This shortcoming is currently circumvented by chemical or physical bracing, which increases the bulk of the total actuator assembly leading to significant cutbacks in device efficiency and utility. Now, we present a molecular design platform for the creation of freestanding actuators that allow for large stroke (>300%) at low applied fields (<10 V μm-1) in unconstrained as-cast shapes. This approach is based on the bottlebrush architecture, which features inherently strained polymer networks that eliminate electromechanical instability and the need for bracing. Through accurate and independent control of the degree of polymerization (DP) of the side-chains (nsc), the DP of the spacer between neighboring sidechains (ng), and the DP of the backbone of bottlebrush network strands (nx), we obtain effective actuation properties on par with commercial actuators with the advantage of lighter weight, lower voltage operation, and ease of fabrication, which open new opportunities in soft-matter robotics.

- Categories: