Researchers Reveal How Solvent Mixtures Affect Organic Solar Cell Structure

Controlling “mixing” between acceptor and donor layers, or solar cell domains, in polymer-based solar cells could increase their efficiency, according to a team of researchers that included physicists from North Carolina State University. Their findings shed light on the inner workings of these solar cells, and could lead to further improvements in efficiency.

Polymer-based solar cells consist of two domains, known as the acceptor and the donor layers. Excitons, the energy particles created by solar cells, must be able to travel quickly to the interface of the donor and acceptor domains in order to be harnessed as an energy source. Researchers had believed that keeping the donor and acceptor layers as pure as possible was the best way to ensure that the excitons could travel unimpeded, so that solar cells could capture the maximum amount of energy.

NC State physicist Harald Ade and his group worked with teams of scientists from the United Kingdom, Australia and China to examine the physical structure and improve the production of polymer-based solar cells. In findings published in two separate papers appearing this month online in Advanced Energy Materials and Advanced Materials, the researchers show that some mixing of the two domains may not be a bad thing. In fact, if the morphology, or structure, of the mixed domains is small, the solar cell can still be quite efficient.

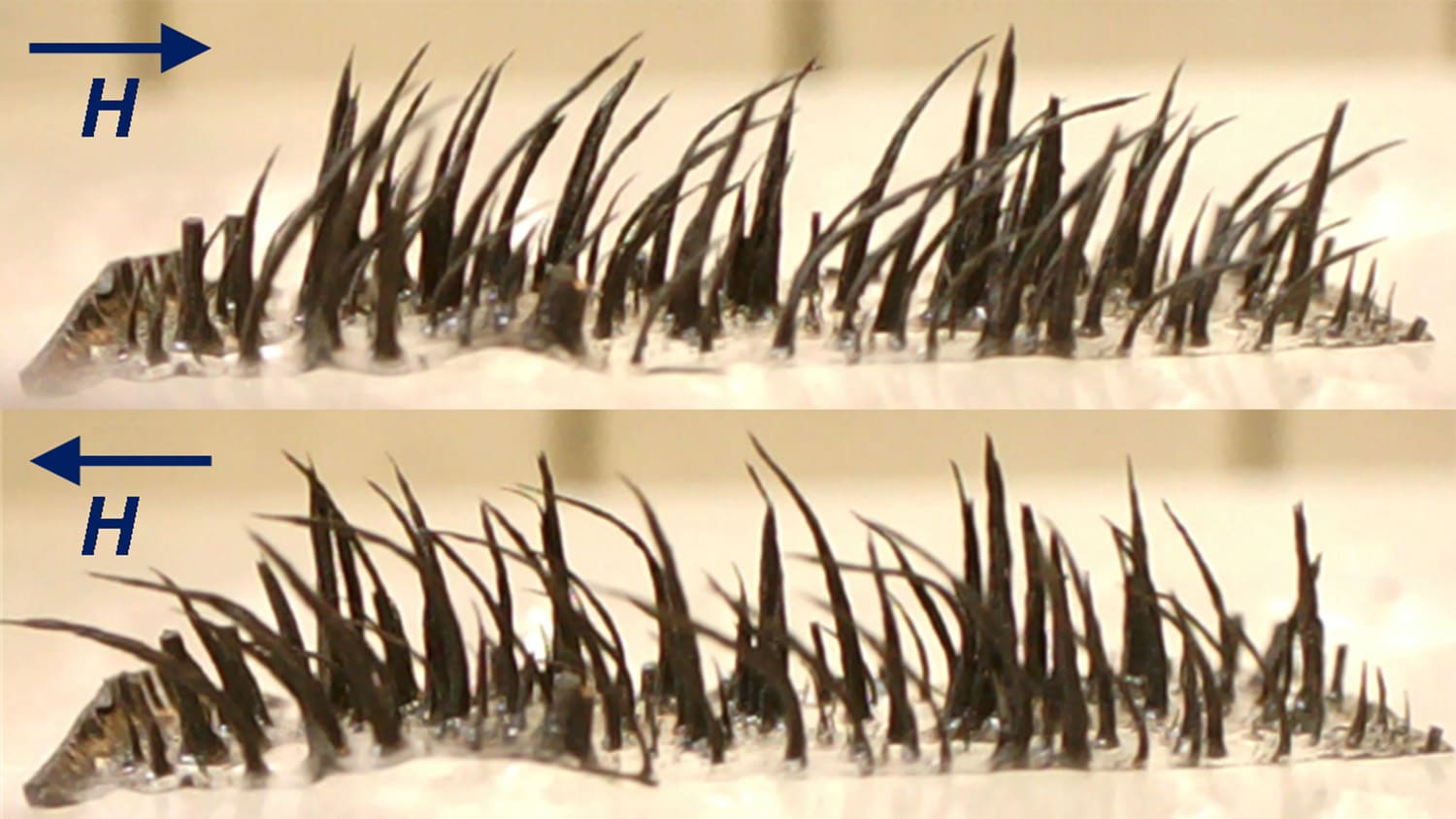

According to Ade, “We had previously found that the domains in these solar cells weren’t pure. So we looked at how additives affected the production of these cells. When you manufacture the cell, the relative rate of evaporation of the solvents and additives determines how the active layer forms and the donor and acceptor mix. Ideally, you want the solvent to evaporate slowly enough so that the materials have time to separate – otherwise the layers ‘gum up’ and lower the cell’s efficiency. We utilized an additive that slowed evaporation. This controlled the mixing and domain size of the active layer, and the portions that mixed were small.”

The efficiency of those mixed layers was excellent, leading to speculation that perhaps some mixing of the donor and acceptor isn’t a problem, as long as the domains are small.

“We’re looking for the perfect mix here, both in terms of the solvents and additives we might use in order to manufacture polymer-based solar cells, and in terms of the physical mixing of the domains and how that may affect efficiency,” Ade says.

The research was funded by the U.S. Department of Energy. Ade is corresponding author on the Advanced Energy Materials paper, with post docs Brian Collins, John Tumbleston and graduate student Eliot Gann contributing to the work. Dr. Zhe Li of the University of Cambridge and Christopher McNeill of Monash University in Australia also contributed. Ade was a contributing author on the Advanced Materials paper, which was co-authored by Ade’s post doc Wei Ma and Professor Jianhui Hou of Beijing’s Chinese Academy of Sciences.

-peake-

Note to editors: Abstracts follow.

“From Binary to Ternary Solvent: Morphology Fine-tuning of D/A Blend in PDPP3T-based Polymer Solar Cells”

Published: Advanced Materials

Authors: L. Ye, S. Zhang, B. Fan, X. Guo, Y. Huang, Prof. J. Hou, State Key Laboratory of Polymer Physics and Chemistry, Beijing National Laboratory for Molecular Sciences, Institute of Chemistry, Chinese Academy of Sciences; W. Ma, H. Ade, North Carolina State University

Abstract: In the past decade, great success has been achieved in bulk hetero-junction (BHJ) polymer solar cells (PSCs) in which donor/acceptor (D/A) bi-continuous interpenetrating networks can be formed and in some recent reports, power conversion efficiency (PCE) even approach 8%. In addition to the intrinsic properties of active layer materials, such as band gaps and molecular energy levels, morphological properties of the D/A blends including crystallinity of polymers, domain size, materials miscibility, hierarchical structures, and molecular orientation, are also of great importance for photovoltaic performance of the devices. Therefore, several strategies including slow growth, solvent annealing, thermal annealing, selection of solvent or mixed solvent have been applied to modify or control of the morphology of the D/A blends. Among these, binary solvent mixtures have been successfully used in morphology control. For example, the dichlorobenzene (DCB) or chlorobenzene (CB)/1, 8-diiodooctane (DIO) binary solvent system has been widely applied in PSC device fabrication process. By mixing a few volume percent of DIO with the host solvent (DCB or CB), efficiencies of many kinds of polymers can be improved dramatically. Besides DIO, other solvents, like 1, 8-octanedithiol (OT), N-methyl-2-pyrrolidone (NMP), 1-chloronaphthalene (CN), chloroform (CF), can also be used. According to these works, it can be concluded that crystallinity, as well as domain size in the blends can be tuned effectively by using binary solvent mixtures, and thus binary solvent mixtures play a very important role in high performance PSCs.

“Absolute measurement of domain composition and nanoscale size distribution explains performance in PTB7:PC71BM solar cells.”

Published: Advanced Energy Materials

Authors: Brian A. Collins, John R. Tumbleston, Eliot Gann, Harald Ade, North Carolina State University; Zhe Li, University of Cambridge, Cambridge U.K.; Christopher R. McNeill, Monash University, Australia

Abstract: The vital importance of morphology on organic solar cell performance is well known, but to date, the lack of quantitative, nanoscale and statistical morphological information has hindered obtaining direct links to device function. Here resonant x-ray scattering and microscopy are combined to quantitatively measure the nanoscale domain size, distribution and composition in high efficiency solar cells based on PTB7 and PC71BM. The results show that that the solvent additive diiodooctane dramatically shrinks the domain size of pure fullerene agglomerates that are embedded in a polymer-rich 70/30 wt.% molecularly mixed matrix, while preserving the domain composition relative to additive-free devices. The fundamental miscibility between the species – measured to be equal to the device’s matrix composition – is likely the dominant factor behind the overall morphology with the additive affecting the dispersion of excess fullerene. As even the molecular ordering measured by x-ray diffraction is unchanged between the two processing routes the change in the distribution of domain size and therefore increased domain interface is primarily responsible for the dramatic increase in device performance. While fullerene exciton harvesting is clearly one significant cause of the increase owing to smaller domains, a measured increase in harvesting from the polymer species indicates that the molecular mixing is not the reason for the high efficiency in this system. Rather, excitations in the polymer likely require proximity to a pure fullerene phase for efficient charge separation and transport. Furthermore, in contrast to previous measurements on a PTB7-based system, a hierarchical morphology was not observed, indicating that it is not necessary for high performance.

- Categories: